BUSINESS

Ceramics Business

Pursuing the possibilities of ceramics to create products of value.

“Ceramics” is one of the three main elemental materials, along with metals and plastics.

Our setters are plasma spray coated, the first in the industry, to provide our customers with products that have stable electrical characteristics and high durability, contributing to the reduction of electronic component firing costs.

Refractories are also classified as ceramics, but the big difference between the products handled in the ceramics division and regular refractories is that their particles are much finer and more homogenous.

For this reason, ceramics have excellent characteristics of wear resistance, heat resistance, heat insulation, low thermal expansion, hardness, insulation and chemical resistance, and this sector is expected to grow further in the future.

At Krosaki Harima, we have targeted the three areas of “fine ceramics,” “kiln furniture for electronic component firing” and “thermal ceramics,” and are developing products that will be flagship products in each of these areas.

We also handle orders for custom-made products and can deliver ceramic products that ideally match the customer’s uses.

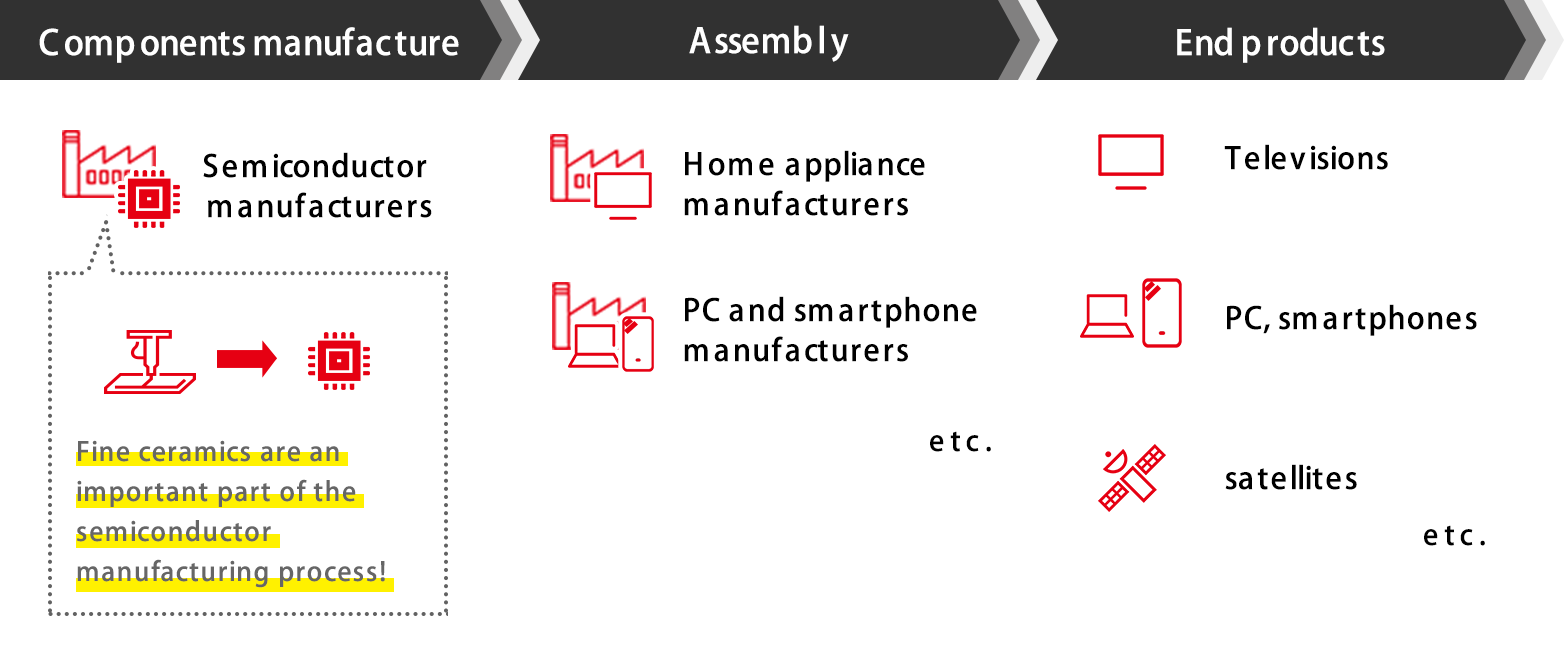

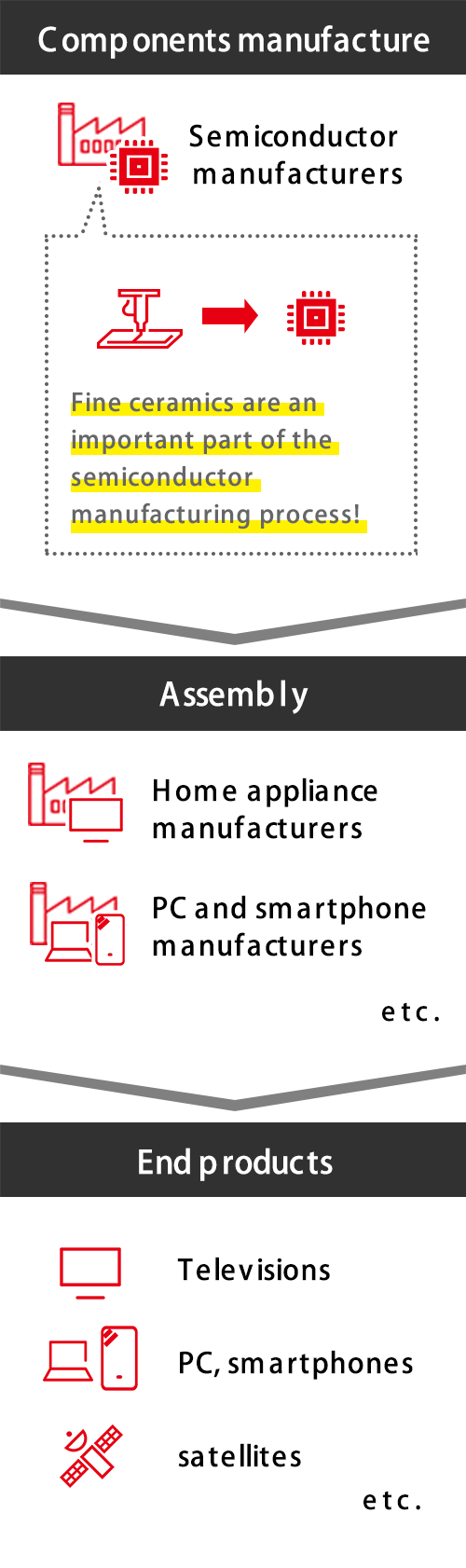

Fine ceramics

With excellent properties of strength, hardness and heat resistance, these materials are also used in the aerospace industry.

In comparison with metals, fine ceramics have the properties of rigidity, good levels of hardness, low thermal expansion and light weight, etc., and can be processed with high precision. These excellent characteristics are fully demonstrated in their use as components in ultra-precision devices.

They are employed as main components in the semiconductor manufacturing devices that are used in the manufacturing processes of the semiconductors (in CPU and memory) that are so essential to PC, smartphones, automobiles and home appliances, etc. They are also used as standards in the calibration of precision measurement devices.

Furthermore, in recent years, we have expanded into the field of aerospace, where our fine ceramics are used as structural components in satellites, and as optical components in earth observation and optical data communications satellites, and have been honing our technologies so that we can contribute to society with new applications.

Main product NEXCERA®

This is an ultra-low thermal expansion ceramic material. One of its most important features is that it has almost zero expansion at near room temperature. It has a higher level of rigidity in comparison with low thermal expansion glass, and is also lighter. It can be worked into more complex shapes than have been possible until now.

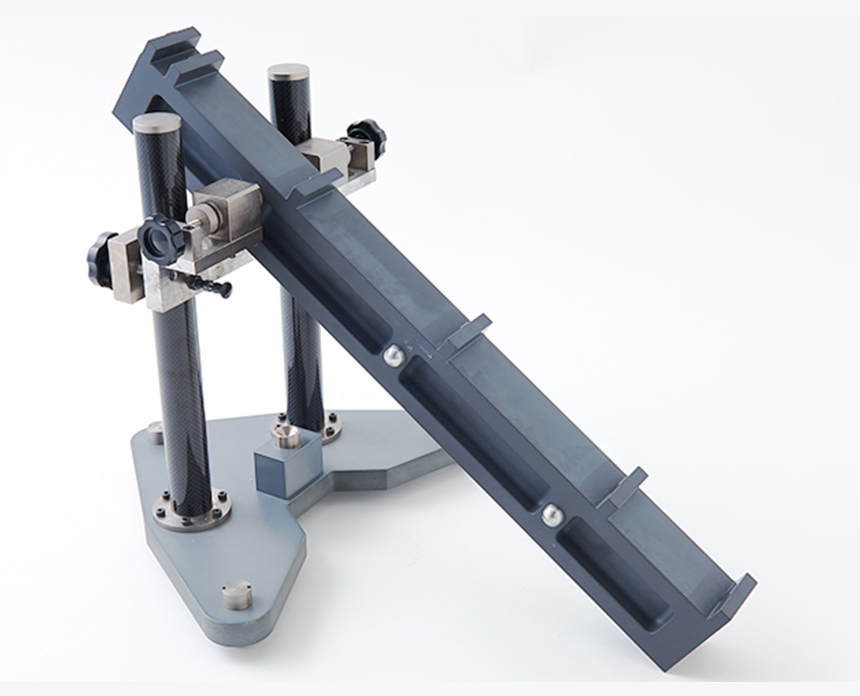

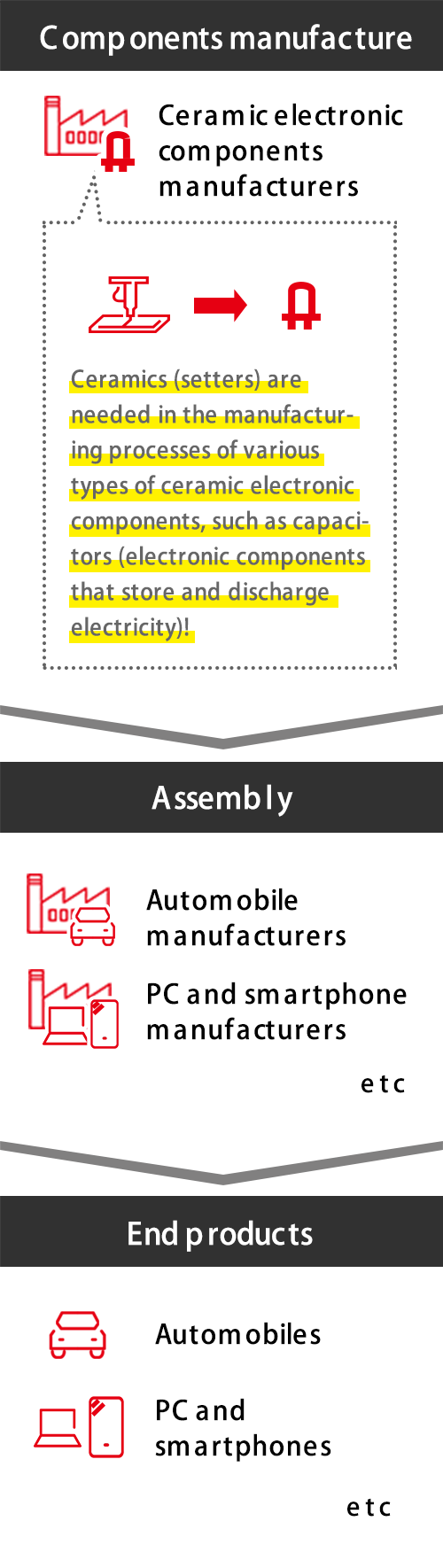

Kiln furniture for ceramic electronic component firing

Supporting the manufacturing processes of communications devices, home appliances, automobiles and other products that are essential to daily life.

Today, multilayer ceramic chip capacitors (MLCC) are used in many communications devices, home appliances and automobiles. They are compact but have a wide electrostatic capacitance range and are used in a variety of circuits, such as noise eliminators, power supply voltage smoothing circuits, filters, etc.

Krosaki Harima’s kiln furniture for electronic component firing (Platect) is used as a “setter” for the firing of these multilayer ceramic chip capacitors.

In the months and years ahead, we will be developing high performance products that can adapt to the changes in electronic component firing processes, and expanding our technology into other areas beyond electronic components.

Main product Platect®

We have developed and manufactured plasma spray coated setters for the first time in the industry. These products realize stable electrical characteristics and excellent durability, and contribute to the reduction of costs in the firing of electronic components.

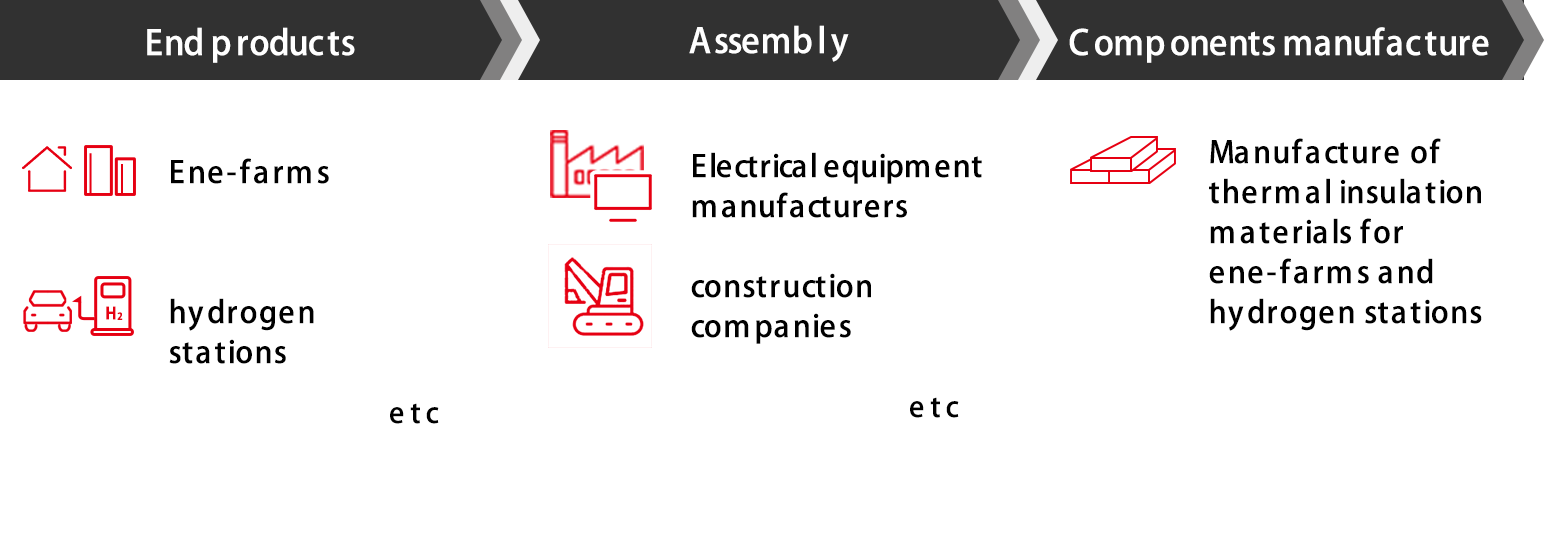

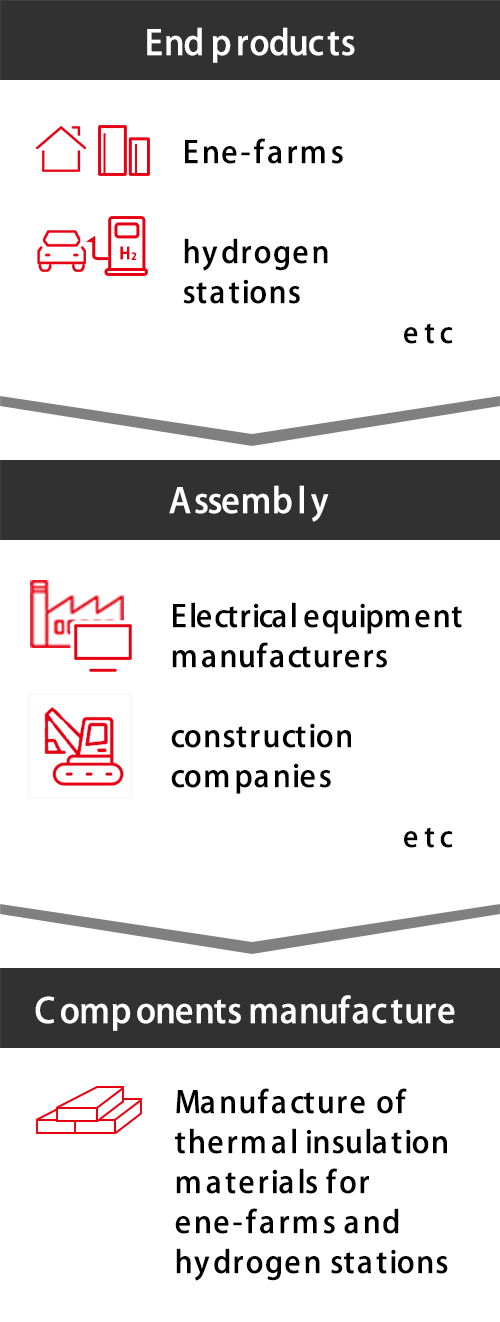

Thermal ceramics

Controlling heat to provide new “heat value”

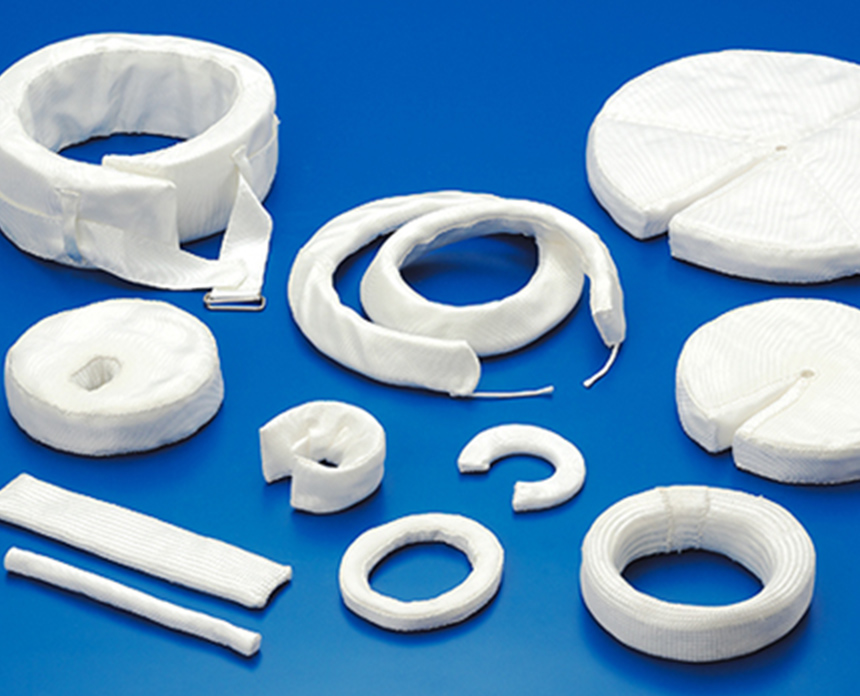

Krosaki Harima’s thermal ceramics are mainly used in products such as thermal insulation materials, heaters and landscape bricks and the like.

These all provide excellent heat control properties and have good heat resistance, heat insulation and workability.

Among our strengths is the fact that we are able to fully leverage knowledge of heat calculation and thermal application, gleaned from our refractories, to provide the kinds of knowledge and technology that cannot be fully covered by construction companies and manufacturers alone.

Amidst the growing calls in recent years for CO2 reductions as measures against global warming, we are contributing to energy saving and environmental improvements such as the development of fuel cell automobiles based on the development of hydrogen and other renewable energy, through the implementation of heat management utilizing our thermal insulation materials, heaters and thermo-controllable landscaping materials.

Main product High performance thermal insulation WDS®

WDS achieves better low thermal conductivity than still air, allowing it to demonstrate excellent heat insulation, thereby contributing to the manufacture of more compact and lighter energy saving devices.

It is also used as insulation in home fuel cells (Ene-farm).