BUSINESS

Engineering & Manufacturing of Sliding Nozzle(SN) devices and Refractory Molds

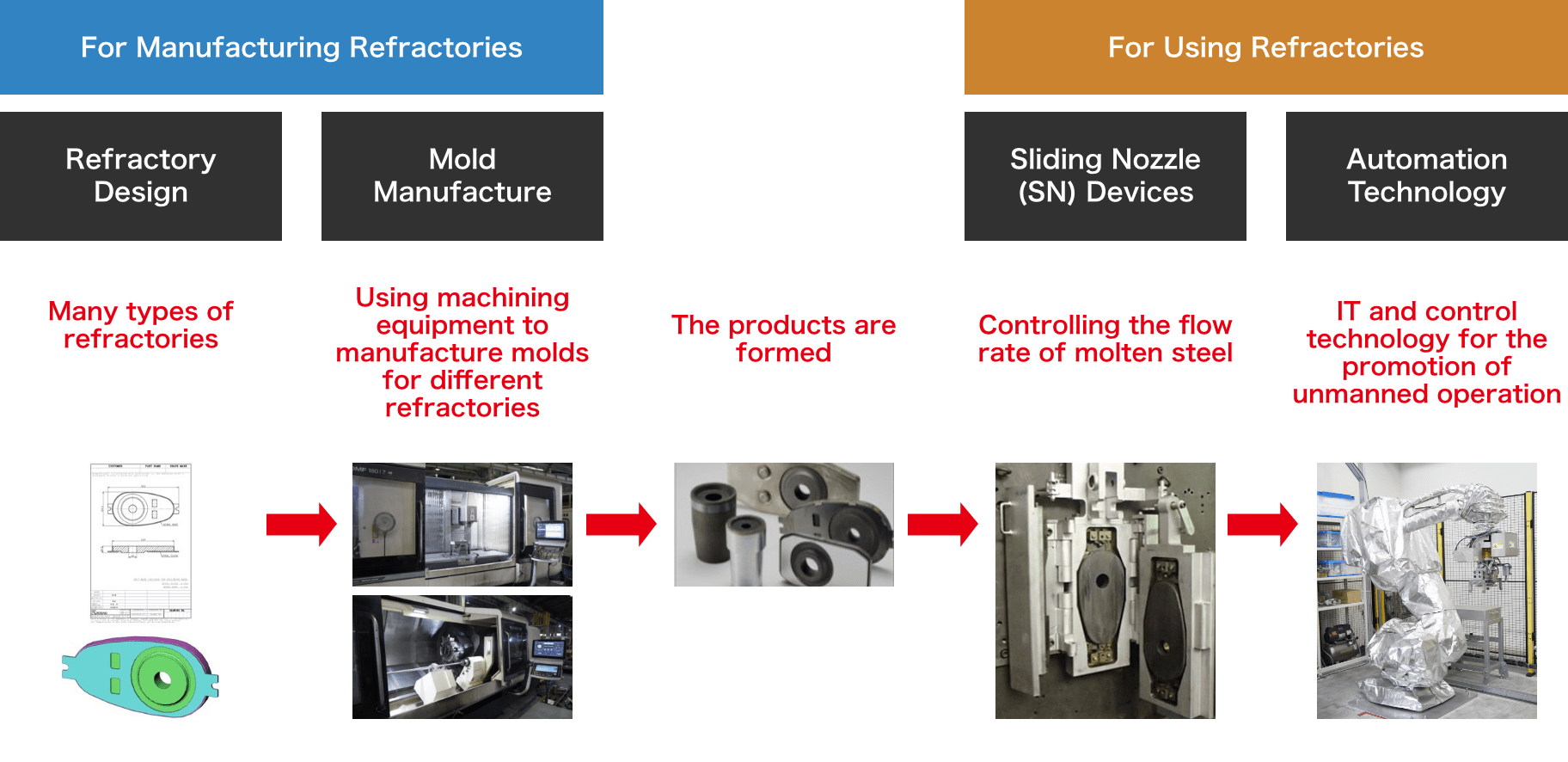

Engineering for the manufacture and use of refractories

~Contributing to refractory manufacturing and the steel producers’ operations~

Krosaki Harima is (We are) not only a refractory manufacturing company. We are also an engineering company that studies, designs and manufactures refractory molds for product application optimization.

By utilizing our engineering capabilities, we are able to maximize refractory performance and provide for the stable steelmaking requirements of our customers.

Our roles to play

Design and manufacturing technologies

~To meet a diverse range of refractory needs~

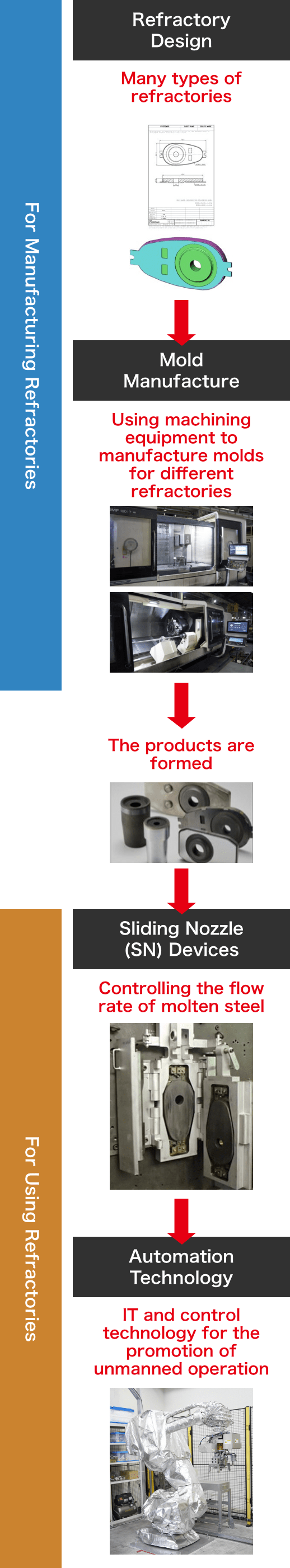

Drawings and molds are essential for the manufacturing of refractories.

The drawings are the foundation of the refractory manufacturing process.

Our technical expertise is incorporated into the design and fabrication of the manufacturing molds. We possess and incorporate unique know-how about individual refractory shapes that support today’s manufacturing process.

We are very proud of the data that we have accumulated and the technological capabilities we have cultivated for the manufacturing of refractories.

Refractory Design

- Refractory material and shape design that matches the equipment

- 3D CAD for efficient design and drafting

- Providing feedback to design by being present at installation

Design technology supporting refractory manufacturing

In addition to quick and precise designs, we are able to provide better refractories to meet our customers’ steelmaking needs by incorporating know-how that has been developed through our vast design and supply history.

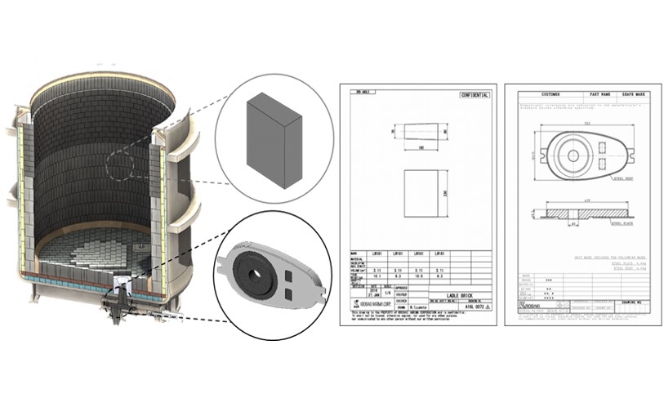

Mold Manufacturing - From Machining to Assembly

- With high machining technology, we can create molds to match any refractory shape.

- Comprehensive production system covers from design to assembly.

Machining technology responding with diversity

We can manufacture a wide variety of products with high precision by applying CAM programming to our laser processing machines and machining centers.

Stable and continuous mold assembly technologies

Our highly skilled workforce assembles and inspects the molds which assure quality control.

“SN device providing stable steelmaking”

“Automation technology contributes toward switching from man-power to handsfree operation.”

Our product design and manufacturing contribute to safer, more stable, and higher quality products that afford our customers improved steelmaking productivity.

SN device

- The SN device controls flow rate of the molten steel.

- The SN device is one of the most important devices for quality steel production

- The SN device is required for improved workability of refractories

What is an SN device?

A Sliding Nozzle, or SN device is used to hold and operated the flow control refractories that are used in the steel making process.

What is the purpose of SN device?

The SN device controls the flow rate of the molten steel passing from the ladle to the tundish or from the tundish to the casting mold by regulating the opening between the holes of plate bricks.

Why is our SN device required?

Maintaining uniform flow rate of molten steel is necessary to produce high quality steel. Additionally, the operational conditions are very severe because molten steel is flowing through the SN device. Our SN device is robust and reliable enough to use under such severe conditions.

Krosaki Harima is a worldwide leader in SN devices and refractories.

We will continue to aim for greater heights.

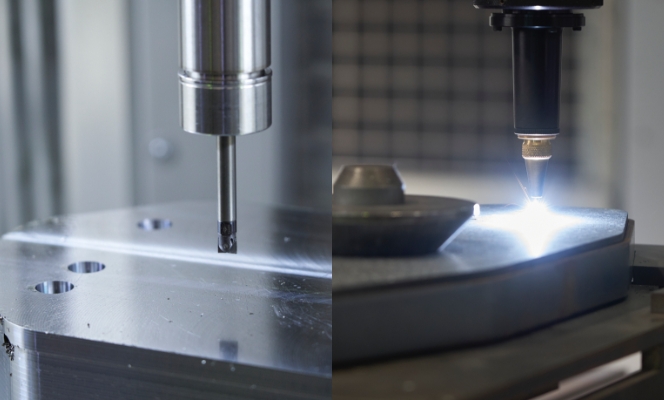

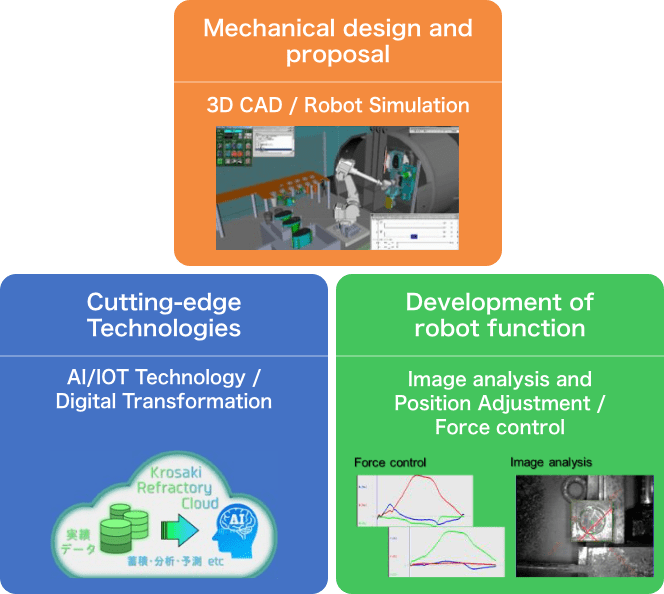

Automation Technology

- Safety Free from hot heavy work

- Stabilization Accurate work, diagnosis, recording

- Laborsaving Reliable work on behalf of skilled workers

- Revolution Transformation into appealing labor style with cutting edge technology

Fusion of automation technology with refractory engineering

(Refractory+Engineering)x(Control+IT)=Krosaki Automation

We provide equipment and devices that realize safe and stable operations in order to support workers.

We are also developing cutting edge technologies such as AI and DX with the aim of further advancements.

REX ROBO

Refractory Exchange Robot for ladle Slide Gate - Opening up new possibilities in operations

Refractory exchange in ladle slide gates has been accomplished by combining Krosaki’s labor saving ladle slide gate "R series" and the general purpose robot.

Krosaki Automation in Refractory and Steel Area