Business

Furnace Business

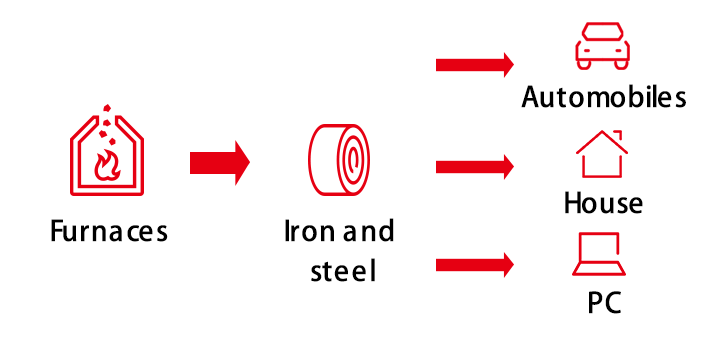

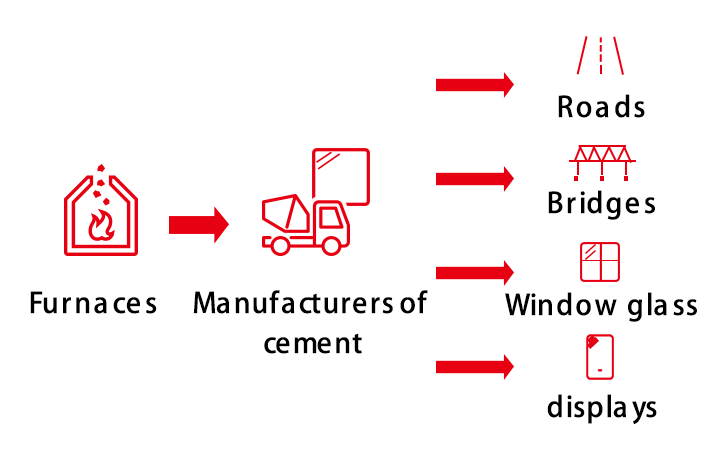

Furnaces are involved in all processes of building the foundations of modern society.

In our daily lives, we are surrounded by many industrial products.

Metal products such as iron, steel, copper and aluminum, ceramic products such as pottery and porcelain, glass, and chemical products such as cement, plastics and chemical textiles; the electrical appliances in our homes, the cars in the streets, ships, buildings, bridges, all of these are assemblies of industrial products.

And, how are these industrial products made?

For example, iron.

Iron can be made from iron ore, or by melting down scrap iron, but in either method, impurities are removed in a step where the iron is melted down, and auxiliary materials added to give semi-finished products.

The semi-finished products then go through a process of reheating, followed by quenching and slow cooling, beating, rolling and surface processing.

After undergoing a wide range of processes, the material then ends up being used in a variety of final products, from the large steel plates used to build ships, to the tiny components used in the tips of ball point pens.

And, how about cement?

Cement is made by mixing limestone and auxiliary materials, then drying and firing at high temperatures.

What do all of these different manufacturing processes have in common?

The answer is “heat.” And the facility that controls the heat is the furnace. Furnaces that are used in the manufacture of industrial products are called “industrial furnaces.”

Heat is an indispensable part of practically every aspect of industrial production, not only in the manufacture of iron/steel and cement, but also glass and chemical products, power generation and incineration facilities, and also the manufacture of the refractories that we produce. And that is the very reason that industrial furnaces exist.

Where do we find furnaces?

Iron and steel manufacturers

These are manufacturers who use iron ore or scrap iron as the raw materials from which to extract iron, which they then form into a range of finished products, such as steel plates, pipes, girders, steel bars, galvanized sheet iron, etc.

Major customers

-

-

Nippon Steel Stainless Steel Corporation

-

JFE Steel Corporation

Materials manufacturers

Manufacturers of cement, glass and chemical products.

Major customers

-

Mitsubishi Materials Corporation

-

Tokuyama Corporation

Incinerators and power plants

Incinerating and melting waste at high temperatures, generating electrical power, etc.

Major customers

Local governments, electric power companies, etc.

What kind of work do we do?

Design

We design and build industrial furnaces (heating furnaces, incinerators, etc.) according to our customers’ requests. Also, even for furnaces that are not designed by us, we can build only the refractory parts, or repair aged furnaces, etc.

Furnace design requires a broad range of knowledge relating to machinery, electricity, instrumentation and refractories, etc., so many of our staff have backgrounds in mechanical engineering and electricity, etc.

Construction

Mainly, we construct refractories for large scale plant (blast furnaces, coke ovens, etc.) at the direction of plant manufacturers.

Maintenance

In post-construction, in steelworks and cement factories and the like, we repair the refractories that get worn through actual usage, and carry out maintenance to ensure that they are always ready for use, 365 days a year.

What’s ahead for the furnace business?

Japan’s steel industry has a long history, and there are still many steelworks that were built in the 1960s that are active today, having been repeatedly repaired and maintained.

Against this backdrop, a major challenge of recent years has been to develop and deliver new technologies in design and maintenance that can adapt to energy related issues, such as energy saving.

In addition, Japanese technology is being put to work by electric furnace manufacturers and the like in countries like Egypt, Indonesia, Taiwan and so on, and we will be focusing ever more attention on global expansion.