EVERCLEAN™

After years of research, we succeeded in a groundbreaking reduction in clogging of the submerged entry nozzle that affects the quality of steel

EVERCLEAN™

Team Member

- Sasaki, a manager at the Technical Research Laboratory

- Lee, a manager at the Technical Research Laboratory

- Katsuki, Head of the Technical Services Group

- Abe, a manager in the Technical Services Group

- Hoshino, a manager in the Technical Services Group

- Otsuka, Head of the Domestic Sales Group

- Kuroda, General manager of the International Sales Department

- Narang, a manager in the International Sales Department

- Igarashi, a manager in the International Sales Department

- Dale, KUI Sales & Field Service-Central/ Sales Analytical Support

- Ito, KUI Technical Supervisor

- Tuomo, KEB Technical Service manager

- Zerei, KEB Customer Service Support

Nozzle clogging is a critical issue that affects the quality of steel

What is the background behind the development of EVERCLEAN™?

Sasaki:

My name is Sasaki, and I work at the Technical Research Laboratory. The development of EVERCLEAN™ was based on the long-standing problem of “clogging of the submerged entry nozzle in continuous casting” faced by steelmakers.

conventional steel, which is referred to as commodity steel, requires that nozzle clogging be prevented in order to improve productivity and reduce costs.

For high-grade steel such as IF steel for automobiles, producing high-strength and lightweight steel sheets is essential to improving safety and fuel efficiency. Moreover, steel sheets for beverage cans must meet extremely high quality standards because the final product is stretched thinly and uniformly, so the inclusion of large foreign objects can easily damage the sheet surface.

Thus, the effects of nozzle clogging and the need for preventive measures differ depending on the type of steel and application, but in any event nozzle clogging is an important issue that affects the quality of steel.

After years of research, we succeeded in developing EVERCLEAN™, the ultimate clogging-resistant material.

What are the technical features of EVERCLEAN™?

Lee:

My name is Lee, and I am also in charge of development at the Technical Research Laboratory. We have taken various approaches to address the issue of “clogging of the submerged entry nozzle” as mentioned earlier by Sasaki.

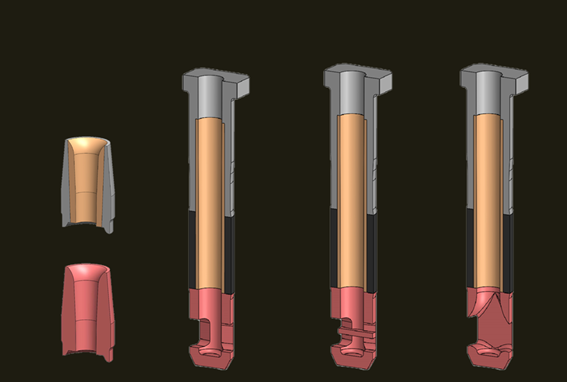

For example, we have developed technologies to Prevent clogging by injecting argon gas and by improving the geometry of the nozzle ports. We have also made further improvements by using anti-clogging materials such as “SiO₂-free material” and “C-free material” to prevent clogging. Moreover, we have been working on technologies to reduce clogging by utilizing chemical reactions to materials such as “ZCG” and “dolomite.”

As a result of the further development of these technologies and many years of research, we have succeeded in developing EVERCLEAN™, the ultimate clogging-resistant material.

EVERCLEAN™ is unparalleled in reducing clogging compared to conventional materials, and the nozzle material is also less trend to corrosion and abrasion.

Typically, materials that prevent clogging have issues with durability. However, EVERCLEAN™ has succeeded in addressing the conflicting issues of “less susceptibility to clogging” and “durability.”

Moreover, varieties are available to allow customers to select the optimum material for the site of use, making it a product that can meet a wide range of needs.

The difficulty of research and development to commercialize new products.

What were some of the challenges and difficulties in the development process?

Sasaki:

The development of this product dates back to 1995. We worked for a long time until the product was ready to be brought to market.

The initial material design involved a number of major issues, including the problem of yield in the manufacturing process in factory and various defects occurring during use by steelmakers.

Addressing each issue took considerable effort and perseverance. This was the most difficult part. Over the course of my R&D career, I once again realized how difficult commercially producing something new is.

Lee:

New materials are developed in R&D are then incorporated into nozzles at the factory, leading to manufacturing of the product. However, optimal manufacturing conditions and adjustments to material are required to maintain consistent production and a high level of quality throughout the year. Determining those conditions and that material is extremely difficult, and we had to work very hard to do so.

In the past, we experienced manufacturing problems and non-conformities in quality when commercially producing other materials. Therefore, research to develop EVERCLEAN™ was guided by the motto, “Products that are easier to make, easier to use, and with more functionality.”

Repeatedly creating numerous prototypes and evaluating them to determine the optimal conditions was a valuable experience for me. As a result of the efforts and cooperation of the everyone in the development, manufacturing, and sales teams, we were finally able to realize new product.

A product that meets the need for improved steel quality and productivity

What sort of needs would this product best meet?

Katsuki:

My name is Katsuki, and I am in charge of technical services. EVERCLEAN™ is a product that helps to improve steel quality and productivity and ensure safety during operations by reducing nozzle clogging, and it is useful at a lot of sites.

Preventing nozzle clogging stabilizes the flow of molten steel in the mold and improves the yield of steel products, thus meeting the needs of customers who want efficient production. It also reduces the risk of a breakout due to the poor flow of molten steel.

Moreover, the use of oxygen gas to clean the nozzle during the casting process is no longer necessary, which reduces the workload and helps to increase process efficiency.

Advantages include reduced costs and improved safety during casting operation.

What are some of the specific advantages of using EVERCLEAN™ for customers?

Abe:

My name is Abe, and I am in charge of technical services. EVERCLEAN™ should improve the quality of semi-finished products by reducing clogging to and blockage of the nozzle and by stabilizing the flow of molten steel in the mold.

Clogging to or blockage of the nozzle inner bore causes an unstable flow of molten steel, resulting in semi-finished products that do not meet manufacturing quality standard.

These have to be discarded or downgraded because they required scarfing or reworking, adding unnecessary steps, energy, and costs. These problems can be prevented through the use of EVERCLEAN™.

The risk of a breakout increases when the flow of molten steel in the mold is disrupted. A breakout is a phenomenon whereby the solidified steel shell in the mold breaks and the molten steel flows out. In such an event, the casted steel has to be cut and removed, and some parts of continuous casting machine have to be replaced due to equipment damage.

Especially in the summer time, breakouts increase the burden on workers and they increase the risk of heat stroke and accidents due to unexpected work, causing a major issue in terms of safety management. EVERCLEAN™ is a product that can help to reduce that work burden and the risk of accidents.

Hoshino:

My name is Hoshino, and I am in charge of technical services. One of the advantages of EVERCLEAN™ is reduced costs. In specific terms, elimination of nozzle clogging allows the stable flow of molten steel and reduces the need to rework the casted steel both in the steelmaking process and also in the customer’s downstream processes, so it should provide substantial advantages in terms of cost.

It should also result in substantial advantages in terms of improving working conditions. Normally, oxygen cleaning is performed in a high-temperature environment. There is a substantial burden on workers and an increased risk of heat stroke and accidents during the summer in particular.

Use of EVERCLEAN™ eliminates nozzle clogging and the need to clean the nozzle, greatly reducing the workload and improving safety.

An awareness of a significant reduction in clogging and helping to reduce environmental impact

What differences do you see between this product and conventional products?

Hoshino:

Customers who are using EVERCLEAN™ have reported a significant reduction in clogging compared to conventional products. In addition, there is less erosion of EVERCLEAN™, allowing it to be used for a longer period of time.

Many customers have also reported that the improved flow of molten steel in the molds has led to improved product quality and productivity. Moreover, our products are designed to reduce environmental impact and have a good reputation.

What are the environmental considerations of EVERCLEAN™?

Abe:

The use of EVERCLEAN™ eliminates clogging of the submerged entry nozzle and allows production with consistent steel quality and a higher yield. This solves safety issues, produces more efficient steel, and reduces energy consumption.

In addition, the reduced use of refractories lead to save energy during manufacturing, reduces the frequency of transportation, and reduces the amount of waste. These are the ways in which EVERCLEAN™ helps to reduce environmental impact.

Highly regarded both domestically and internationally, including installation and support systems

What is the process for installing EVERCLEAN™?

Otsuka:

My name is Otsuka, and I am in charge of domestic sales. Installation of EVERCLEAN™ is a customized process tailored to customer’s needs.

First, we examine and evaluate the usage environment and suggest optimal product specifications. Specifically, we will design the product with the optimal material and material location. After a brief trial installation, we will proceed to full-scale installation. After installation, we provide ongoing support through regular troubleshooting and technical advice based on data the customer shares with us.

What sort of feedback have you received from customers?

Igarashi:

My name is Igarashi, and I am in charge of the International Sales Department. Installation of EVERCLEAN™ has greatly alleviated the problem of nozzle clogging, and the product has been praised for “improving steel quality and production efficiency” and “reducing costs.”

We have been recognized for our prompt and attentive response, which is why our support system is favored by customers.

Narang:

My name is Narang, and I am also in charge of the International Sales Department. We have been praised by many customers, and this has led to inquiries from new customers.

We are currently performing trial installations for a lot of customers, both in Japan and overseas. We will continue to assist our customers in resolving their problems by enhancing cooperation with sales offices, sales companies, and local agency in each region.

Providing more customer value from Japan to the rest of the world

How do you see the market developing in the future?

Kuroda:

Multiple customers in Japan are already using EVERCLEAN™, and we believe that there is also a substantial need for it in major steel mills overseas. In particular, demand for lightweight and high-strength steel sheets of high-grade automotive steel is increasing along with global interest in being environmentally conscious. Therefore, EVERCLEAN™ technology to prevent nozzle clogging is expected to become increasingly important in the future.

Conventional steel also requires improved productivity, reduced costs, and improved energy efficiency, and the need for measures to prevent nozzle clogging is expected to grow further in the future.

We are committed to providing greater customer value by customizing specifications to provide optimal products that meet the various needs of our customers.

What sort of technological development do you wish to pursue in the future?

Sasaki:

We would like to create a system that allows minor changes to be made in accordance with the operating conditions of customers who are already using EVERCLEAN™ and potential customers who are considering using it in the future.

We are also continuously researching and developing new materials to reduce nozzle clogging in all usage environments.

What can you tell us about your future endeavors?

Katsuki:

We will continue to develop new technologies and actively expand into new markets. We will also focus on product development to further increase customer value and work to enhance customization to meet customer needs and enhance our support system.

Interviews with members of overseas sales companies

North American Sales Company KUI

What is expectations about “EVERCLEAN™” from customers?

Customer C is unable to exchange clogged SENs due to “Mono-block type SEN”, so the tundish life is limited by the SEN service life in which clogging is the most common factor. Customer has a big expectation of EVERCLEAN™ which has the excellent feature of clogging prevention from the view point of safety and extended SEN service life.

What is other expectations to EVERCLEAN™ apart from quality, production loss (yield rate) and safety?

There is a global focus on the environment including CO & CO2 emissions. According to new technology, EVERCLEAN™, we expect to contribute to improvements in steel production as well as a reduction of energy consumption.

In addition, since the usage amount of refractories will be reduced, we believe we can contribute to the preservation of the environment by saving energy when producing refractories, reducing the demand on transportation, and lessening the amount of industrial waste.

European sales company KEB

What is expectations about “EVERCLEAN™” from customers?

Customer A has the issue of frequent SEN replacements due to clogging during casting, leading to operational disruptions and increased SEN consumption.

Customer A expects significant reduction of SEN replacement by applying EVERCLEAN™, which effectively prevents SEN clogging. This will improve casting efficiency and enhance overall productivity.

Customer B has the issue that the replacement of SENs due to clogging is not possible because of the Mono-block type SEN, requiring hazardous operations such as oxygen cleaning to maintain functionality.

Customer B anticipates EVERCLEAN™ for its exceptional anti-clogging properties, as it can significantly enhance safety by eliminating the need for dangerous maintenance operations. This technology offers a safer and more efficient solution, reducing operational risks and improving overall workplace safety.

The first trial of SENs applying EVERCLEAN™ in the actual casting at Customer A. What is the result ?

The amount of clogging has been substantially decreased, ensuring smoother operations.

There is potential for an increased steel yield, which will be validated during the industrial trials.