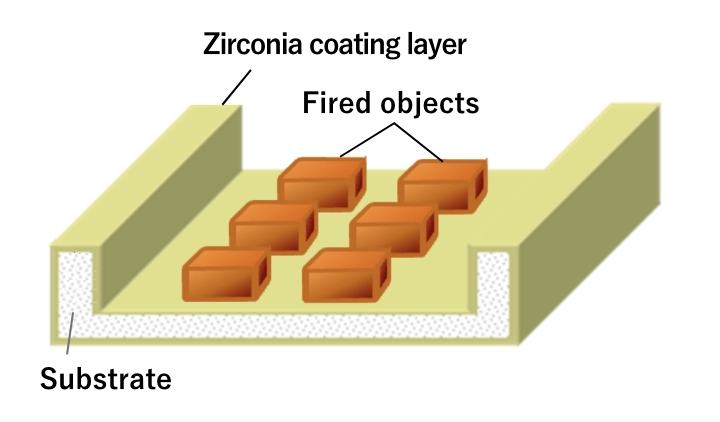

In manufacturing electronic components such as capacitors, firing is carried out in firing furnaces exceeding 1,000 degrees Celsius. PLATECT™ was developed as a container (hereinafter referred to as a setter) for holding electronic components during this process.

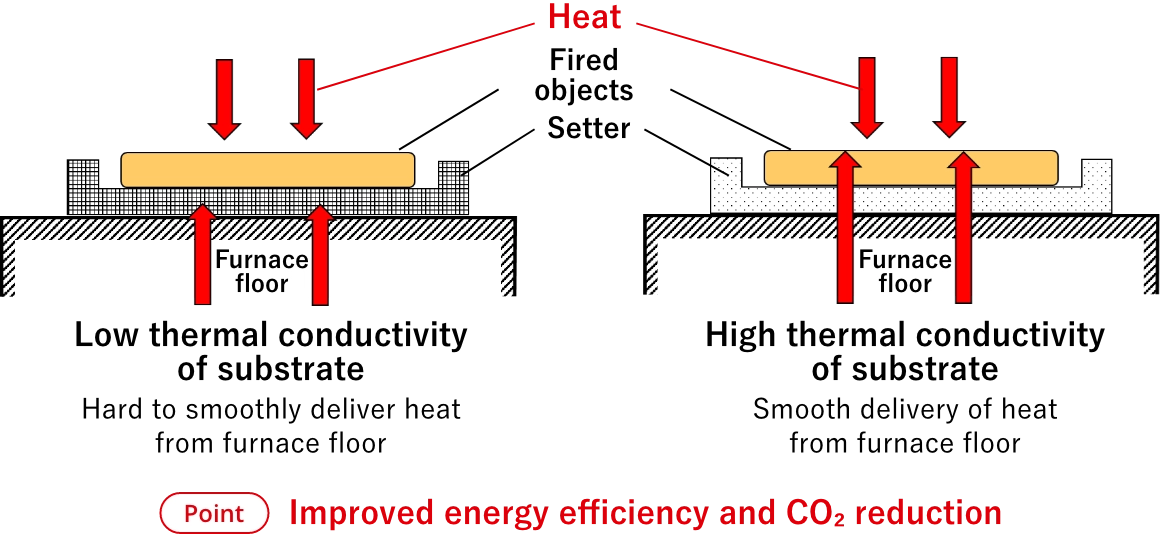

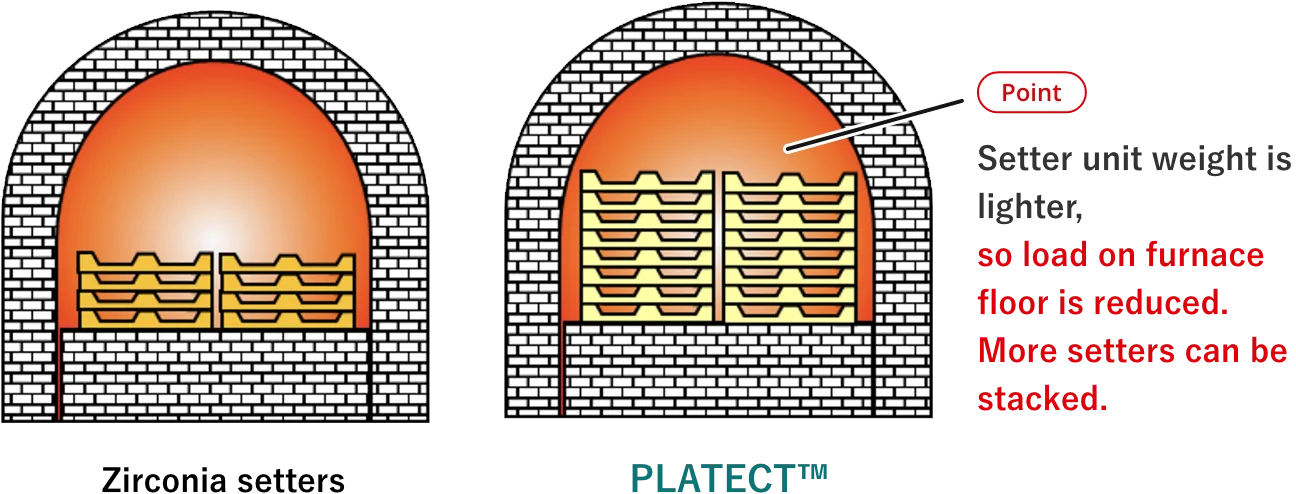

Compared to conventional zirconia setters, PLATECT™ is lighter and has higher thermal conductivity, and its coating lasts longer than that of cold spray coatings.

For the firing of multilayer ceramic capacitors (MLCC) in particular, we boast a high global market share of approximately 40%.

These products are also used to fire electronic components other than MLCCs, such as varistors and thermistors, and there are even cases of adoption in heat treatment of metal parts.