Dry-Free™

A challenge that overturns conventional wisdom by eliminating drying process for monolithic refractories.

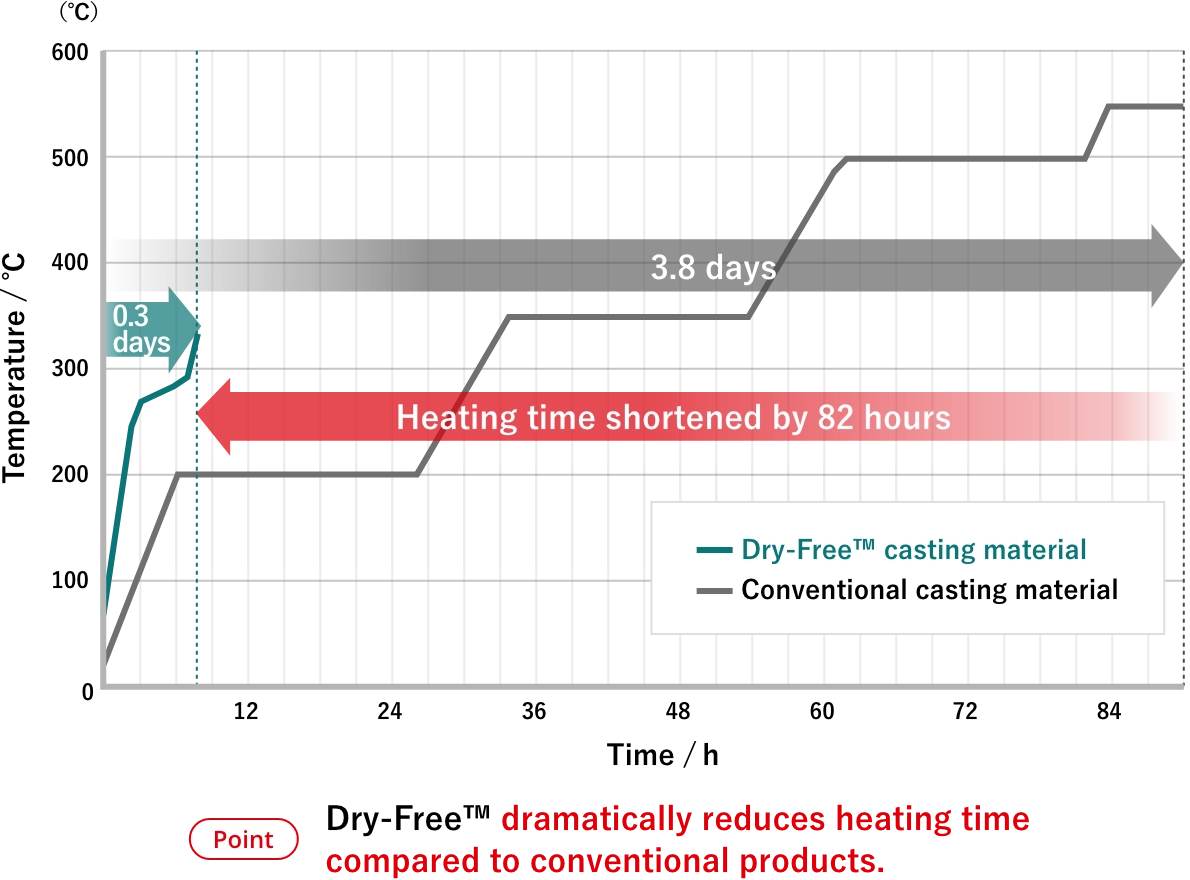

Conventional drying processes require 90 to 100 hours, during which time the temperature inside the furnace must be carefully controlled in tens of degrees Celsius increments. With the introduction of Dry-Free™, however, the drying process itself is no longer necessary, and the furnace can be started up with only the temperature rise necessary for incineration. As a result, start-up can now be accomplished in as little as eight hours.