NEXCERA™

Applications ranging from semiconductors to outer space by capitalizing on a low coefficient of thermal expansion and light weight. Exploring the limitless possibilities of ceramics.

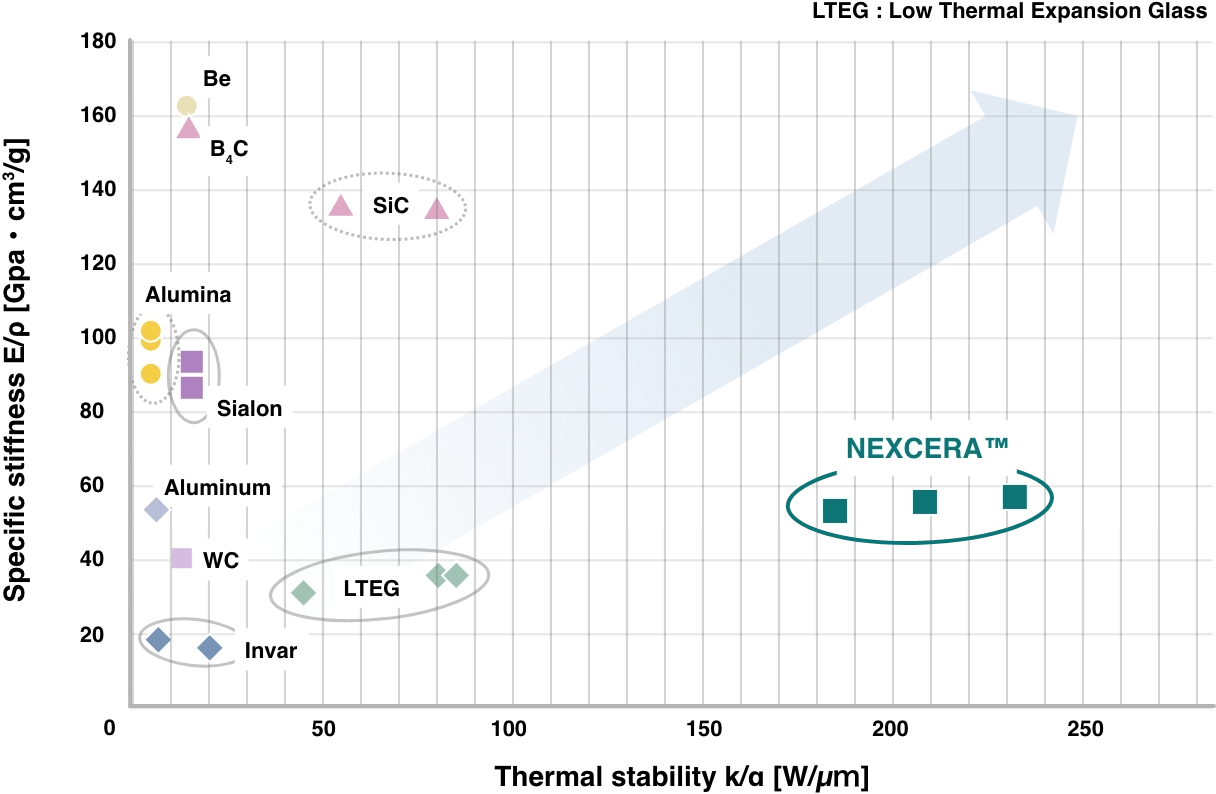

In anticipation of the increasing demand for higher precision alongside the evolution of semiconductors, we began developing a material capable of achieving near-zero thermal expansion at room temperature ahead of our competitors around the year 2000. The result of that effort was the development of NEXCERA™.