NEXCERA™

Applications ranging from semiconductors to outer space by capitalizing on a low coefficient of thermal expansion and light weight. Exploring the limitless possibilities of ceramics.

NEXCERA™

Team Member

- Sato, Head of the Ceramics Research Group, Technical Research Laboratory

- Ishitobi, Head of the Production Engineering Group, Fine Ceramics Department, Ceramics Division

- Hattori, Head of the Quality Engineering Group, Fine Ceramics Department, Ceramics Division

- Fujisawa, Manager of the Ceramics Sales Department, Ceramics Division

Higher precision is required in conjunction with the evolution of semiconductors

What was the background behind the development of NEXCERA™?

Sato:

My name is Sato, and I am head of the Ceramics Research Group. The development of NEXCERA™ was prompted by the need for a material for semiconductor lithography equipment.

Steel was originally used in the stages of semiconductor lithography equipment. However, as the speed of semiconductor lithography increased, the need arose for a lighter, more stiffer material that was less susceptible to deformation. As a result, a ceramic called alumina was used. Later, as semiconductor miniaturization progressed, thermal expansion began to affect the precision during exposure, and silicon nitride-based “sialon” was used as a material with a low coefficient of thermal expansion.

As semiconductors evolved, higher precision would presumably be required, so starting in around 2000 we began working to develop a material with almost no thermal expansion near room temperature ahead of our competitors. What we developed is NEXCERA™.

Low thermal expansion ceramics with almost no thermal expansion

What are the technical features of NEXCERA™?

Hattori:

My name is Hattori, and I am the head of the Quality Technology Group, which was involved in the development of NEXCERA™. As I mentioned earlier regarding the development process, the most significant feature of NEXCERA™ is that it is a low thermal expansion ceramic with little thermal expansion near room temperature. Capitalizing on this unique feature, NEXCERA is lightweight and highly stiffer, helping to improve performance in the area of semiconductor manufacturing equipment.

Characteristics of the ceramic are that it uses diffusion bonding to join materials and that it lacks voids. These characteristics allow customization to meet our customers’ demanding requirements. Moreover, we have the advantage of being able to fashion components with complex designs from a single material for mirrors.

Fujisawa:

My name is Fujisawa, and I am the Manager of the Ceramics Sales Department. From a sales standpoint, we can inform customers of the advantages of NEXCERA™ based on its technical features, i.e., “zero thermal expansion with almost no thermal expansion near room temperature,” “aging stability to retain a consistent shape over a long period of time,” “extremely precise components providing a high level of processing precision,” “highly stiffer and lightweight,” and “mirror characteristics for optical applications.”

Thus, NEXCERA™ is used in various fields that require advanced performance characteristics, including the field of semiconductors.

Repeated improvements have led to an expanded product lineup

What were some of the challenges and difficulties in the development process?

Sato:

The development of NEXCERA™ was originally based on the theoretical calculation that zero thermal expansion could be achieved by combining constituents with positive and negative thermal expansion. A small sample made in the laboratory yielded results that were in line with those calculations.

When the product was actually produced commercially in large sizes, however, various problems arose, such as unstable thermal expansion and an uneven color.

To solve these problems, we adjusted the constituents added and thoroughly controlled the raw materials. Constituents were sometimes affected by the state of management of raw materials in particular, so we sought to provide consistent products by enhancing quality control. We had to overcome many more difficulties in the actual process of commercial production than in development itself.

Hattori:

However, thanks to repeated trial and error, we were also able to expand the product lineup, which was also a major achievement. Currently, the NEXCERA™ lineup has grown to four or five types, and we believe that this is the result of repeated improvements.

Making the impossible possible

What sort of customer needs do you think this product is best suited for?

Fujisawa:

Our sales representatives in the field have received requests from customers for improved performance, such as “higher stiffness” and “lighter weight,” as well as requests for “reduced costs” and “quick delivery.” However, responding to all of those requests is difficult, so we are determined to meet the needs of our customers by “making the impossible possible.”

Ideally, use of NEXCERA™ will improve the performance of machinery and equipment and contribute to society. Currently, NEXCERA™ is mainly used in the field of semiconductors, but in the future, we are looking to expand into various fields such as space exploration. We would like to further expand possibilities while being attuned to more detailed needs.

Capitalizing on low thermal expansion and a lighter weight in applications from semiconductors to outer space

What led to your expansion into the space industry?

Ishitobi:

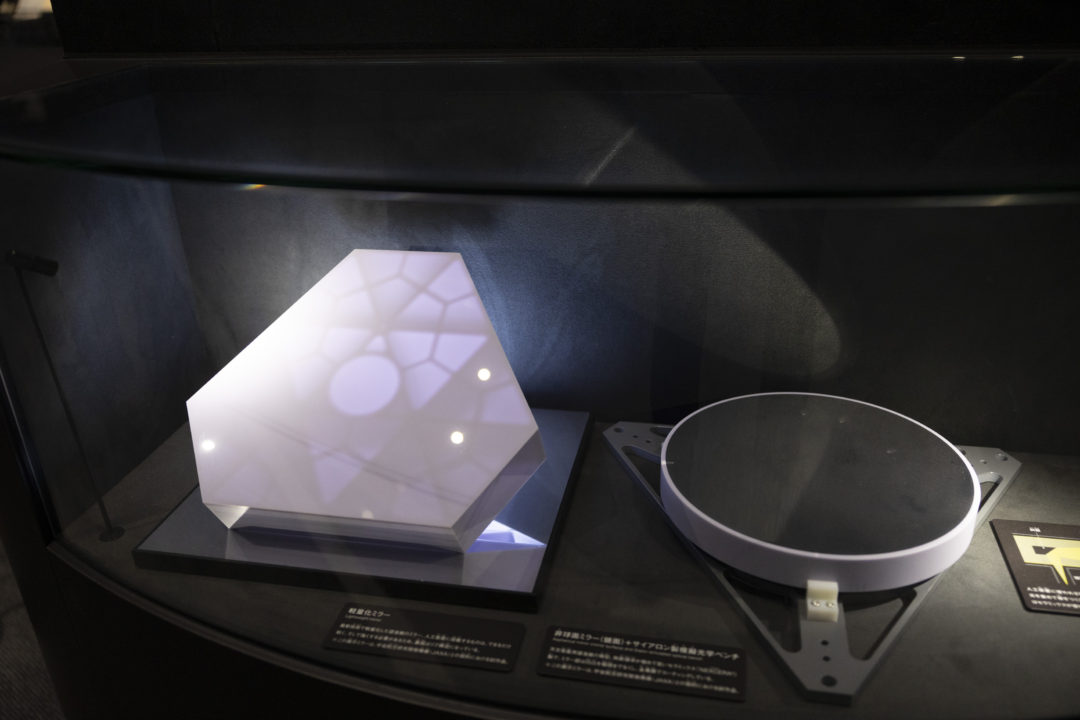

My name is Ishitobi, and I am the head of the Production Engineering Group. More than a decade ago when we exhibited NEXCERA™ at an exhibition, the product caught the attention of a supervisor of development at JAXA. The person was in charge of measuring how the structures of satellites behave when subjected to temperature changes and asked if NEXCERA™ could be used as a reference material to accurately determine their movement in space.

When we manufactured and delivered NEXCERA™ as a reference standard, it was praised as an excellent material. Later, we were asked if NEXCERA™ could be used as a mirror for optical satellites to improve efficiency compared to conventional materials, and we are now working on the use of NEXCERA™ as a mirror.

How does your product differ from the competition?

Hattori:

Low thermal expansion glass is one of the most widely used low thermal expansion materials today. This material has been used in the areas of semiconductor manufacturing equipment and the space industry, where high-precision positioning is required.

NEXCERA™ is about 1.5 times more stiffer than low thermal expansion glass, and this feature is highly appreciated by our customers. Due to its characteristics, glass may have issues with dimensional stability over long periods of time, but an advantage of NEXCERA™ is its excellent dimensional stability over long periods of use.

What are the environmental considerations of NEXCERA™?

Sato:

As mentioned at the beginning, in the field of semiconductors, the stages of semiconductor lithography equipment move at high speeds, and NEXCERA™ has the advantages of being lighter in weight and requiring less energy for movement. This can help to save energy. Being lightweight is also an important factor in the space industry. Launching a rocket requires a large amount of fuel, and reducing the weight of components can reduce fuel consumption.

Moreover, an indirect effect of using NEXCERA™ is that it should allow finer semiconductors to be manufactured with semiconductor lithography equipment, leading to reduced power consumption. Demand for semiconductors is expected to increase substantially in the future as IoT and AI become more widespread. Therefore, we believe that NEXCERA™ will make a major contribution in terms of reducing energy consumption.

Exploring the limitless possibilities of ceramics

What sort of market expansion are you planning for the future?

Fujisawa:

We would like to grow the space industry as one of the pillars of our business in the future. Currently, the space industry is already a 50-trillion-yen market, and it is expected to reach 84 trillion yen by 2030 and exceed 100 trillion yen by 2035. We are seeking to expand our business related to the space industry by installing our ceramic products, such as NEXCERA™ mirrors, in space satellites.

However, there are some challenges. Currently, the recognition and widespread use of ceramic products in satellites is still limited, and Krosaki Harima still has limited name recognition in the space industry. Therefore, we would like to work to improve the brand recognition of Krosaki Harima while actively touting the appeal and superiority of our products, such as NEXCERA™.

What is the direction of future technological development?

Hattori:

I believe that ceramics have limitless possibilities. They have been used in a wide range of industries, including semiconductors, the space industry, and medicine. In the fields of electronics and optical products in particular, performance has been dramatically improved by replacing conventional materials with ceramics.

Moore’s law, put forth by Intel in 1965, is a prediction of the future of semiconductor density. Technological development progressed in accordance with this law for several decades, but over the past few years, however, concerns have arisen that the limits of this law may have been reached. However, there is a history of limits being overcome each time through technological innovation.

Improvement in the performance of ceramics has played a vital role in this technological innovation. In fact, we believe that technological evolution would not have been possible without ceramics.

We have very high expectations for ceramics in the future as well. In particular, high stiffness to facilitate a higher resolution and speed and high thermal conductivity to minimize the effects of heat generated in the equipment environment will be important technological challenges in the future. To achieve these goals, we will continue to develop materials at an even faster pace than before.

Ishitobi:

Our strength lies in the fact that we have developed technology in accordance with the needs of our customers. This is the reason why we have been able to survive in the market, and we believe that this stance is one we should maintain in the future.

We will continue to focus on the field of semiconductors, which has been a major market thus far, but we also intend to actively take on the challenge of space development, which is a new market. We will aim for further growth based on “Providing the world’s highest customer value,” which is the goal of our business.