REX-ROBO™

Collaboration between humans and robots, creating a more comfortable workplace. Achieving efficiency and consistent operation by the technology, expanding options to attract valuable human resource.

REX-ROBO™

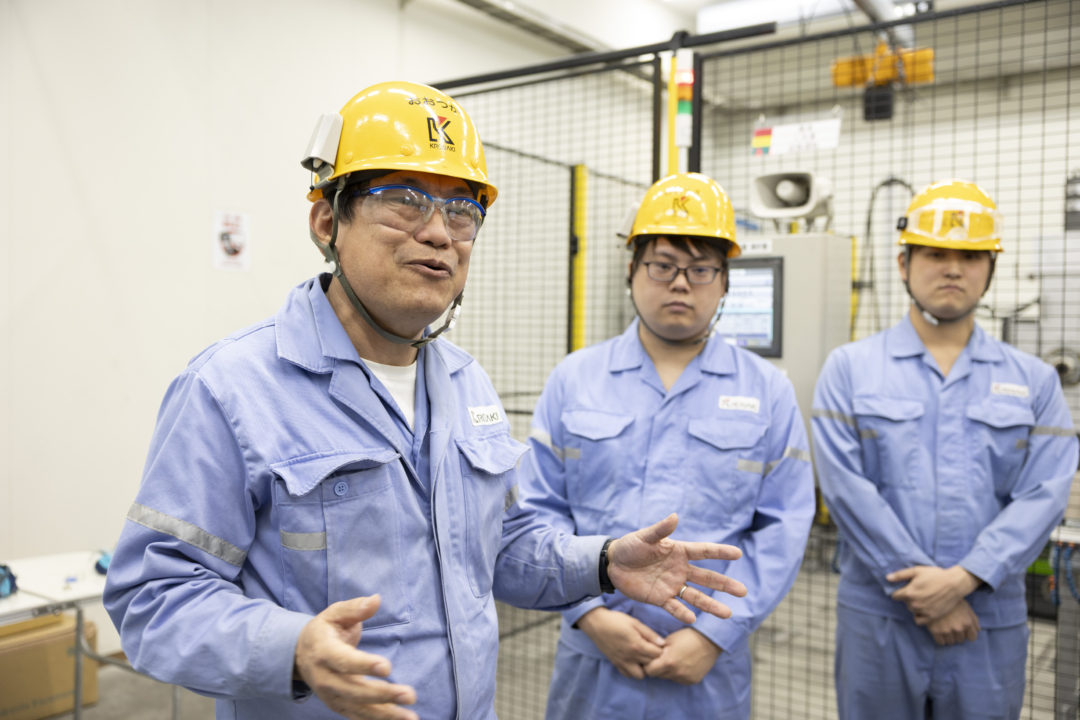

Team Member

- Yoshimura, Development Supervisor

- Otsuka, Department Manager

- Yamaguchi, Manager

- Onoue, an engineer

- Yumihata, a service engineer

- Nimura, an engineer

- Muta, an engineer

Improving safety and reducing the workload were urgent issues

What was the background behind the development of REX-ROBO™?

Yoshimura:

My name is Yoshimura and I am the head of the Automation Engineering Group. I have been a member of the group since development first started in 2015.

REX-ROBO™ was originally developed to reduce the workload and improve safety in the steel manufacturing process. Development also sought to add “Newer” to “Better, Cheaper, Faster,” which is our company motto.

In specific terms, in the process of manufacturing steel, molten iron (molten steel) is poured from a ladle into casting equipment. In this process, our SN Device is used to adjust the flow rate of molten steel. The SN device has 2 refractory plates with holes that are called SN plates, and the flow rate of molten steel is adjusted and controlled by sliding these 2 plates.

However, these plates are used in a high-temperature environment, so they deteriorate with each casting and need to be replaced periodically. Currently, these plates are replaced manually, which is dangerous and involves a lot of heavy labor in a high-temperature environment.

Therefore, improving safety and reducing the workload were urgent issues.

There have been attempts at automation in the past, but they failed to yield satisfactory results. However, recent advances in robot control technology have made more advanced automation feasible, raising expectations for new development and prompting the forming of our team.

Trial and error, starting with “What is a robot?”

What were some of the challenges in the development process?

Yamaguchi:

I am currently a member of the Slide Gate Engineering Group and in charge of sales, but I have been involved in the development of REX-ROBO™ since the very beginning. Development started with four members including Yoshimura, the head of the group. We started by going to a specialized training facility to learn “what is a robot?” and to obtain certification in robot operation.

A particular challenge was learning to use 3D simulations to verify operations prior to verification with the actual robot. This verification has now become an integral part of the development process and is fully utilized.

During the initial round of verification, adjustment of the position of the robot arm’s camera sensors did not go well, and a lot of trial and error was involved. However, repeated rounds of improvements and verification resulted in smooth operations.

Products that meet the need for a more comfortable working environment

What needs does REX-ROBO™ meet for your customers?

Muta:

My name is Muta, and I am in charge of development in the Automation Engineering Group. Plate replacement and maintenance work is performed in a high-temperature environment of 40 degrees Celsius or higher. Handling heavy refractories requires a great deal of strength, which is why it is also referred to as “heavy physical labor.” Thus, younger workers tended to steer clear of working in such a harsh environment.

Therefore, this product was developed to protect workers from heavy physical labor in high-temperature environments and to reduce their workload, thereby creating a more comfortable working environment. And by eliminating variability in work, we want to promote the advancement of of diverse human resources, like women, and to create a workplace where even young, inexperienced workers can work consistently without being driven away.

Equipment that can be operated by young workers and women, expanding the options for attracting human resources

What are the advantages to your customers?

Yumihata:

My name is Yumihata, and I am in charge of technical services in the Slide Gate Engineering Group. I am in charge of technical services for the installation of specific equipment. To begin with, installation of the SN device is a prerequisite for REX-ROBO™ installation. Use of the SN device simplifies working with molten steel and speeds up the process.

I would also mention that combining the SN device with REX-ROBO™ can reduce the workload for operators and create a safe and more comfortable working environment.

Many customers are also interested in the fact that this approach reduces variability in work due to people and the environment and it allows consistent operations to continue.

Main advantages

- Improves safety by reducing the load on and hazards to workers

- Can be operated by young workers and women, expanding options for attracting human resources

From “work” to “operation,” collaboration between humans and robots improves efficiency and consistency

What was the concept behind the development of REX-ROBO™?

Nimura:

My name is Nimura, and I am in charge of development in the Automation Engineering Group. REX-ROBO™ stands for “Refractory Exchange Robot,” which is a combination of “R” for refractory and “EX” for exchange. As the name suggests, it means a “refractory exchange robot.”

Our development concept was to “shift from work to operation.” Rather than focusing on full automation, we sought to create automation that emphasizes collaboration between humans and robots.

Of course, having robots perform all tasks would be ideal, but we know that robots are good at some tasks and not good at others. Therefore, we have tried to improve efficiency and consistency while appropriately relying on humans in places where human senses are required.

What environmental considerations are there?

Yumihata:

I actually go to the customer’s site to provide technical services. First of all, the SN device allows a reduction in the workload on workers as well as faster and simpler work. These services help to create a “more comfortable working environment.”

In addition, we have achieved automation that combines the 4 elements of improved safety, consistent work, a reduced load, and work reforms, and we are promoting environmental friendliness.

How are your customers responding?

Muta:

We have a demonstration room with a demo model at our head office and plant in Yahata for customers to visit. Replacing the SN device was previously thought to be difficult to automate, but many customers have been surprised to see how smoothly the REX-ROBO™ can replace it.

This approach has also been praised for its ability to improve safety and make operations more consistent.

What is the process for installing the product?

Onoue:

My name is Onoue, and I am in charge of sales in the Slide Gate Engineering Group. I was originally in the Development Department, but now I am in charge of sales, drawing on my knowledge when I visit our customers. Thanks to your support, we have received a contract for the first REX-ROBO™ in Japan.

The installation process requires the installation of the SN device as a prerequisite. If an SN device has already been installed, it will be replaced by a new SN device. When initially installing SN devices, one will be installed. Once it is operating consistently, other devices will then be installed.

In any event, a detailed study is conducted on-site to determine the layout and specifications before proceeding with the installation. The device undergoes test operation before delivery and then a trial run on-site, after which it is put into full-scale operation. Even after it is in operation, we of course conduct periodic inspections, check usage, and provide on-site advice.

As a team, we seek to facilitate autonomy by incorporating AI and to develop more advanced robots

What markets do you plan to expand into in the future?

Onoue & Yamaguchi:

Our presentation at an exhibition in Germany in 2023 garnered a great deal of attention in markets overseas. Following the full-scale operation of the first unit in Japan, we have decided to offer our product in North America. Based on its operational performance, the Company plans to further expand its business in both domestic and overseas markets.

What sort of products would you like to develop in the future?

Nimura:

In addition to the areas where automation is currently underway, we plan to promote product development while identifying additional needs. We will also continue to consider the possibility of utilizing the product’s existing features in other applications.

In addition, we will work as a team to facilitate autonomy by incorporating leading-edge AI features and to develop more advanced robots.

Finally, what is your outlook for the future?

Otsuka:

My name is Otsuka, and I am the Manager of the Engineering Department, which is responsible for the sales and development of REX-ROBO™. Two customers in Japan and overseas are already using REX-ROBO™, and we will work intently to assist them. The issues faced by and the needs of steel mills are the same not just in Japan but also around the world. We will continue to accurately ascertain those needs and develop products that lead to solutions.

We believe that REX-ROBO™ will be a benchmark for the future. We are working to enhance our organization to help achieve that goal.