TOUGHMAX™

Bringing the rest of the world a revolutionary product from Asia that extends the life of refractories in converters by more than 40%

TOUGHMAX™

Team Member

- Yamasaki, Technical services for Taiwan, Krosaki Harima Corporation

- Sogano, Manager, International Sales Department, Refractories Global Sales Division, Krosaki Harima Corporation

- Huang, Sales & Technical Service, Krosaki Harima Taiwan Office

Reducing the wear on magnesia-carbon bricks and extending the campaign life of converters

What sort of product is TOUGHMAX™?

Sogano:

My name is Sogano and I deal with China Steel Corporation (CSC) in Taiwan as part of our International Sales Department.

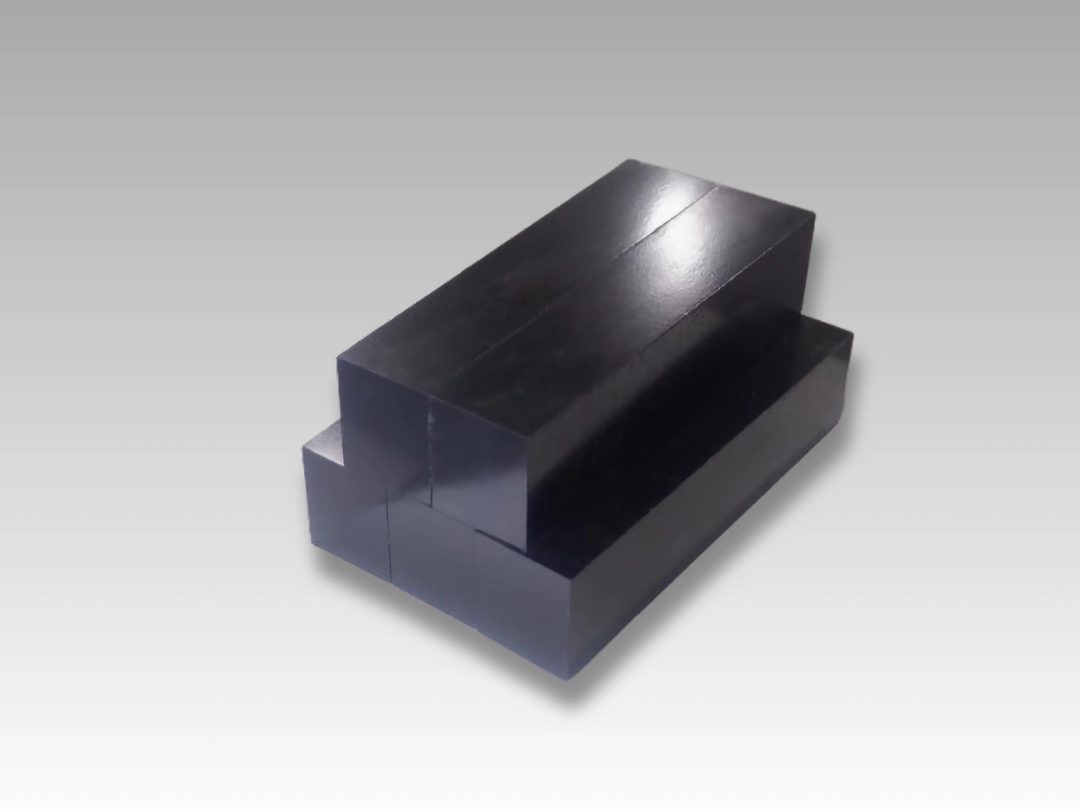

TOUGHMAX™ is a type of refractory brick called a “magnesia-carbon brick,” which is made mainly from magnesium oxide and graphite, and is mainly used in steel mills. TOUGHMAX™ is now used at converter in which pig iron is transferred into steel at steel mills.

Huang:

My name is Huang, and I work at Krosaki Harima’s Taiwan Office. I am in charge of dealing with customers in Taiwan and accompanying Krosaki Harima staff from Japan. TOUGHMAX™ is currently being used by customers in Taiwan as well as in Japan, and the product is highly regarded.

What are the advantages of using TOUGHMAX™?

Yamasaki:

My name is Yamasaki, and I am in charge of technical service for and technical improvement of furnace refractories, which include TOUGHMAX™, as part of the Furnace Technology Department.

TOUGHMAX™ is used in a piece of equipment called “converter,” so I will start by briefly explaining what converter is.

A converter is an exceptionally large equipment, several meters in diameter and up to 10 meters tall, into which molten iron (molten pig iron) and scrap are charged. Carbon is removed from the iron through a process called “decarburization” to make steel.

The inside of a converter is a harsh environment where the thermal, physical and chemical conditions vary greatly. Therefore, appropriate materials and products with different properties need to be selected depending on where the bricks are located in the converter.

These thermal and chemical conditions also cause magnesia-carbon bricks to gradually wear away, which is a phenomenon known as “erosion” or “wear.”

Customers stop the converter after it has been in operation for a certain period and then remove or replace the bricks while checking how worn they are. In the interim, the converter cannot be operated, decreasing production efficiency. Therefore, “refractories with a longer life” are desperately needed in order to keep the converter in operation as long as possible without stopping.

TOUGHMAX™ was developed specifically for use in the “charging pad” of the converter. The high performance of TOUGHMAX™ in this area will extend the life of refractories in the charging pad, which has limited the converter’s campaign life and thus enable the converter as a whole to be operated for longer.

Huang:

I often observe an installation when bricks in the converter are replaced at a customer’s site. So converter is an extremely huge equipment, even the slightest misalignment of bricks can greatly affect the wear of the bricks subsequently, that a high level of precision in the installation is required.

Sogano:

The criterion for evaluating refractory’s performance is typically how much steel can be produced during the campaign. As Yamasaki mentioned, products need to be selected “appropriately”, simply using the highest quality products for the entire converter is not sufficient. That would be wasteful in terms of cost. Therefore, determining “where efforts should be focused” and appropriately installing high value-added products is important.

Huang:

To that end, a crucial step is to engage in thorough discussions with the customer on-site and to actually observe the converter to determine the places with particularly severe wear.

What is the difference between TOUGHMAX™ and conventional refractories?

Yamasaki:

Compared to conventional magnesia-carbon bricks, TOUGHMAX™ is, as the name implies, “Tough”. That is, it has superior fracture resistance and is highly durable in harsh environments.

Sogano:

Among the “refractories” used in converters, TOUGHMAX™ is a product that can help to reduce environmental impact.

Toughness is evident in the brand name

How did you come up with the name TOUGHMAX™?

Yamasaki:

The name “TOUGHMAX™” comes from a “high resistance to fracture,” or “toughness,” which is the product’s main feature. The point is that TOUGHMAX™ provides a higher level of resistance to fracture than conventional products.

The name was chosen following numerous discussions among dozens of the members working on this product to best convey the properties and advantages of the product to our customers. We believe that the name adeptly expresses the product’s appeal.

Huang:

The words “TOUGH” and “MAX” are ones we often hear in our everyday lives, so customers can easily envision the product’s features. When they actually use the product, they should be able to sense its “resistance to fracture” in particular.

Sogano:

From a sales standpoint, we are very pleased to be able to offer our brand name products in addition to the technical explanations we have provided thus far.

TOUGHMAX™ is a product that we can confidently suggest to our customers because it relates to “the environment” in addition to having a long life and cost advantages as a refractory.

What should customers be mindful of when using TOUGHMAX™?

Huang:

Compared to conventional magnesia-carbon bricks, TOUGHMAX™ has no special precautions regarding its usage or storage conditions. The product can be used in the same manner as magnesia-carbon bricks that are currently in use.

Reducing the use of molten iron and helping to reduce CO₂ emissions from blast furnaces

What is TOUGHMAX™’s role as an environmentally friendly brand?

Yamasaki:

In a converter, both molten iron, which is made from iron ore in a blast furnace, and reusable scrap are used as sources of iron to make steel. When molten iron is used, a large amount of CO₂ is emitted during blast furnace operation. In contrast, the use of scrap can greatly reduce CO₂ emissions, so from the perspective of environmental impact increasing the proportion of scrap is preferable.

However, molten iron and scrap are charged from the top of the converter to the “charging pad” a few meters to a dozen meters below. Molten steel has much higher specific gravity than magnesia-carbon bricks and its weight differs considerably even under the same size. It is as if a block of steel were falling from the second or third floor of a building, and refractories are subjected to such a massive impact.

Therefore, increasing the amount of scrap use would cause severe wear on the magnesia-carbon bricks used in the charging pad, reducing the campaign lives the converter.

However, the use of TOUGHMAX™ allows the life of refractories in the charging pad to be extended. As a result, the bricks last longer and less molten iron is used even if more scrap is used. In other words, TOUGHMAX™ is an environmentally friendly brand in that it reduces CO₂ emissions from blast furnaces.

Sogano:

The longer a converter is in operation with TOUGHMAX™, the less often the bricks need to be removed or replaced. We believe that the reduction in the frequency of maintenance work itself will also lead to a reduction in environmental impact.

Huang:

Large pieces of heavy machinery are needed to demolish and maintain converters, so reducing the frequency with which those pieces of machinery are used will also contribute greatly to the environment.

Demonstrated effectiveness in Taiwan as well as in Japan

What sort of customers use TOUGHMAX™?

Sogano:

When the product was first developed, it was used in the charging pads of the converters in Japanese customers. Compared to conventional magnesia-carbon bricks, TOUGHMAX™ has a proven track record of extending the life of refractories and reducing CO₂ emissions.

Given this track record, we are working to expand and further improve our product lineup.

In 2023, TOUGHMAX™ was introduced in Taiwan as the first step in expansion overseas. We gave a presentation on TOUGHMAX™ at a technical seminar there. We had the opportunity to describe the product to several customers individually, and it was well received.

Yamasaki:

One of our customers who is using TOUGHMAX™ said, “We confirmed that TOUGHMAX™ has a 40% or longer life more compared to conventional products.”

Praised for technical capabilities that eclipse price

Did you encounter any difficulties while expanding into Taiwan, your first overseas market, that differed from those in the Japanese market?

Sogano:

We received numerous requests from our Taiwanese customers, especially in terms of price, but we honestly did not know whether or not they would be willing to use TOUGHMAX™, which is more expensive than conventional products, on a trial basis. However, a highly significant achievement for us was to fully appreciate the technical advantages of TOUGHMAX™ for customers, which led them to use it.

This was largely due to a combination of various factors, including individual presentations, building trust over the years through technical services, and the recent increase in interest in achieving carbon neutrality.

As a result, our Taiwanese customers favor TOUGHMAX™ over conventional products.

Yamasaki:

In order to expand into the Taiwanese market, we started by ascertaining actual conditions at customers’ sites. In order to ascertain the campaign life of bricks, we focused on the fact that our customers regularly monitor the condition of their converters, and we collected and analyzed as much of those data as possible.

As a result, we were able to clearly demonstrate with objective data that the charging pad limits a converter’s life.

We had felt that there was a lack of a decisive factor in garnering customer interest in the Taiwanese market, but we believe that TOUGHMAX™ is a “game changer” that will alleviate that situation.

Huang:

I remember how hard collecting data was at the time.

Yamasaki:

Thanks to our efforts, we were able to precisely ascertain the overall wear of converters and suggest the optimal placement of TOUGHMAX™ based on that information.

Are there any other difficulties you had?

Yamasaki:

One index that is used to indicate the features of TOUGHMAX™ is a value called “fracture toughness”, which is seldom used to evaluate conventional refractories. Therefore, we had a hard time convincing our customers of the meaning and value of this index.

Huang:

The same was also true in Taiwan, where many of our customers were not familiar with the term “fracture toughness”. Therefore, we tried to explain it as clearly and carefully as possible by using diagrams, photos, graphs, and sketches.

In addition, Japanese technical staff were in charge of the development of TOUGHMAX™, so I served as an interpreter when more detailed explanations were needed. A lot of preparation was required in terms of language, but this enabled us at Krosaki Harima to give a unique presentation, and customers found it highly appealing.

Cultivating global markets and developing new applications

What are your thoughts on future developments?

Yamasaki:

For starters, we hope that TOUGHMAX™ will be increasingly used in the charging pads of converters.

Currently, our track record is limited to Japan and Taiwan, but we would like to inform of TOUGHMAX™ to our customers around the world in places like Europe, North America, and South America. We hope they appreciate its effectiveness once they actually use it.

In addition, there are data indicating that TOUGHMAX™ has improved thermal spalling resistance compared to conventional magnesia carbon bricks. Therefore, we believe that TOUGHMAX™ has the potential to be used in other parts of a converter, such as the bottom blowing tuyere. We would like to work to further expand the areas of use in the future.

What are your plans for the future?

Sogano:

As part of the refractory industry, we have worked to reduce CO₂ and produce environmentally friendly products.

TOUGHMAX™ is a completely new product that both meets “customer needs” and that “reduces CO₂ emissions,” which conventional products were unable to do.

As a sales representative, I would like to make suggestions more in line with customers in the future so that more customers become aware of the appeal of TOUGHMAX™.

Yamasaki:

We believe that TOUGHMAX™ technology has the potential to be effective not only in converters but also in other equipment.

We will continue to provide our customers with higher value-added products by drawing on the knowledge we have gained from developing TOUGHMAX™ to further improve the product and to develop new products.

To that end, we would like to, through technical services, gain the further trust of the customers who use our products, such as TOUGHMAX™, and who work with us.

Huang:

As the person in charge of the Taiwanese market, I will start by closely following up with local customers.

We believe that our achievements in Taiwan will serve as crucial data for global expansion in the future, so we will further enhance the sharing of information with Japanese engineers and help to improve the competitiveness of Krosaki Harima’s products and facilitate our expansion overseas.