The KHC Way

The Krosaki Harima Corporation Vision

「 MASTERING HEAT 」

Utilizing our heat technology

Mastering heat, empowering industries, and creating a brighter future

Our Purpose

with which we are a global force in advanced comprehensive ceramics entities, driving industrial progress and building a sustainable world where future generations can thrive

-

Resist

Heat-resistance

-

Insulate

Thermal insulation

-

Transfer

Thermal transference

-

Control

Heat control

-

Stable

Low expansion

We are advanced comprehensive ceramics entity with the technology of “Mastering Heat”.

Heat is something that is indispensable to the enrichment of our lives.

Since ancient times, people have created vessels, mastered fire and heat, created materials from the resources of the earth, and generated energy.

Throughout this process, ceramics have always existed as an indispensable element to all of that.

For over these 100 years,we have created value by "mastering heat", ensuring stable, reliable quality even under the ultra-high temperatures of the earth and the extremely low temperatures of outer space.

We will continue to share the value we co-create through our business activities with all stakeholders and remain committed to building a sustainable society,

in line with our Purpose and Vision – “mastering heat, empowering industries, and creating a brighter future”.

Our ceramic products that control heat across every industry

2000℃

Melted steel

1600°C

1600℃

Melted pig iron

1500°C

1200℃

Bonfire flames

900〜800°C

800℃

400℃

200℃

Deep-fry oil

180°C

Bathwater

40°C

0℃

Home freezer

-18°C

Lowest recorded

temperature on Earth

-98°C

Temperature of space

-270°C

-273.15℃

Product Material

Refractory material range

Iron and Glass

Iron and Plastic

Steel

2000℃〜800℃

Energy conservation and the environment

1200°C〜900°C

Biomass power generation/Incinerator

Maximum operating temperature 1000℃

Electronics

Platect 1400°C〜1000°C

ALN Heater 300°C〜220°C

Hole plate 23°C

Medical and Space

Mirror 70°C〜 -12°C

Overall/Body 139°C〜 -114°C

Steel

The melting point of iron is 1,538℃. The path through which molten iron and glass pass, as well as the receptacle, must be made of a material that can withstand both high temperatures and chemical erosion. We support the world's steel industry by manufacturing refractory products that take advantage of the heat resistant properties of ceramics, as well as design and construct industrial furnaces that use these refractories.

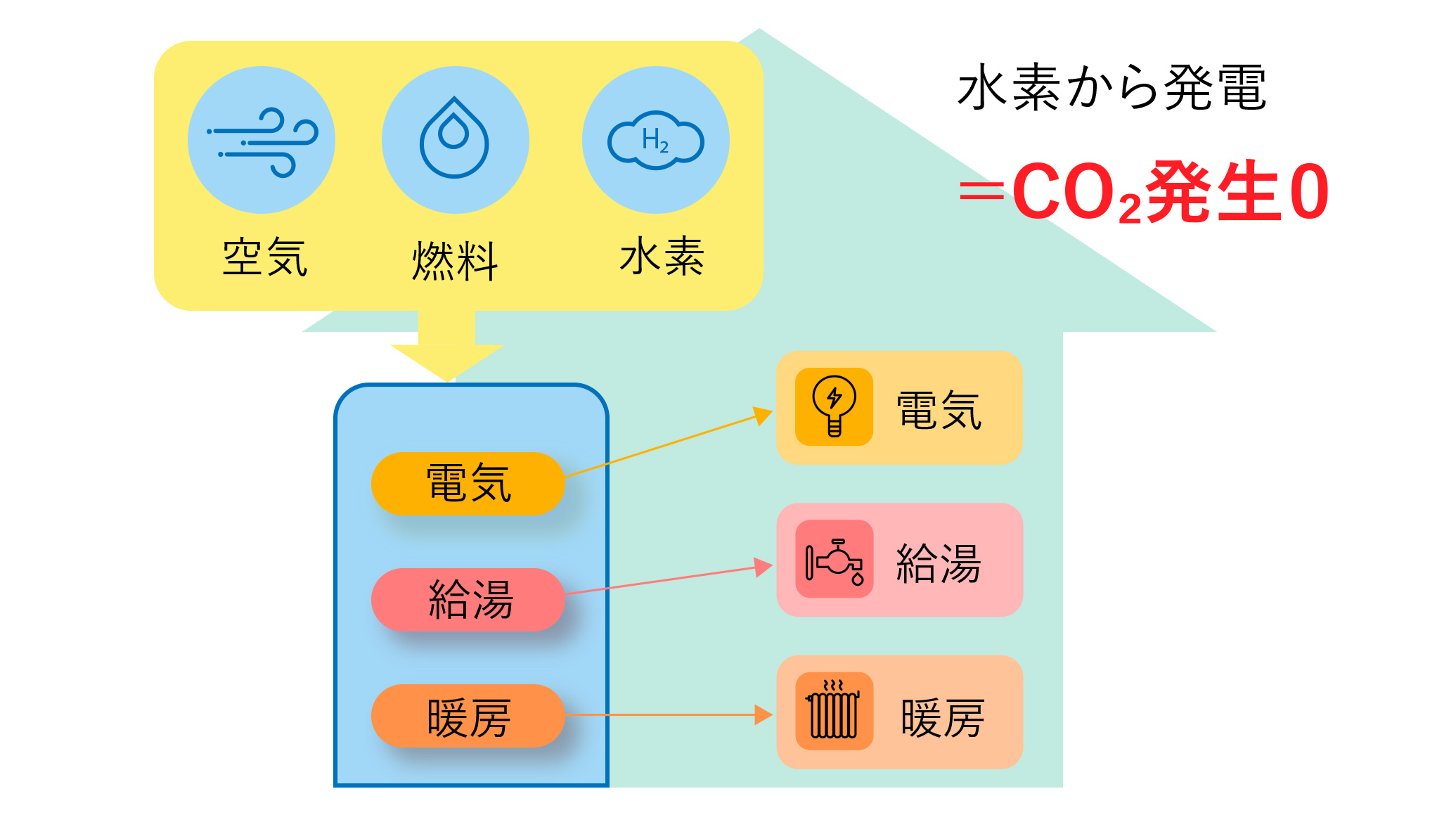

Energy conservation and the environment

We design and construct incinerators with excellent waste heat recovery, supply and construct refractories for biomass generation plants, supply heat insulating materials for ENE-FARM, contribute to improving the safety of lithium-ion batteries by providing heat insulating materials and market landscape materials that provide heat control. As a whole, our products and solutions contribute to the reduction of CO2 emissions in society.

Electronics

Mobile phones have become an integral part of our lives in today's society. Our products are used to fire laminated ceramic capacitors which are essential in the manufacture of mobile phones. We also design and produce liquid crystal display manufacturing equipment that meets the needs of our customers by using our knowledge of heat calculations and applications from our work in refractory manufacturing.

Medical and Space

The fine ceramics manufactured by our company are more rigid than metals, have high hardness, low expansion and are light in weight, and can be processed with high precision. These ceramics demonstrate excellent characteristics as parts for ultra-precision equipment. In recent years, we have expanded into the field of space with structural parts for satellites and optical parts for Earth observation and optical data communication satellites, and are refining our technology so that we can contribute to society using our technology in new ways.