Carbon Neutral Initiatives

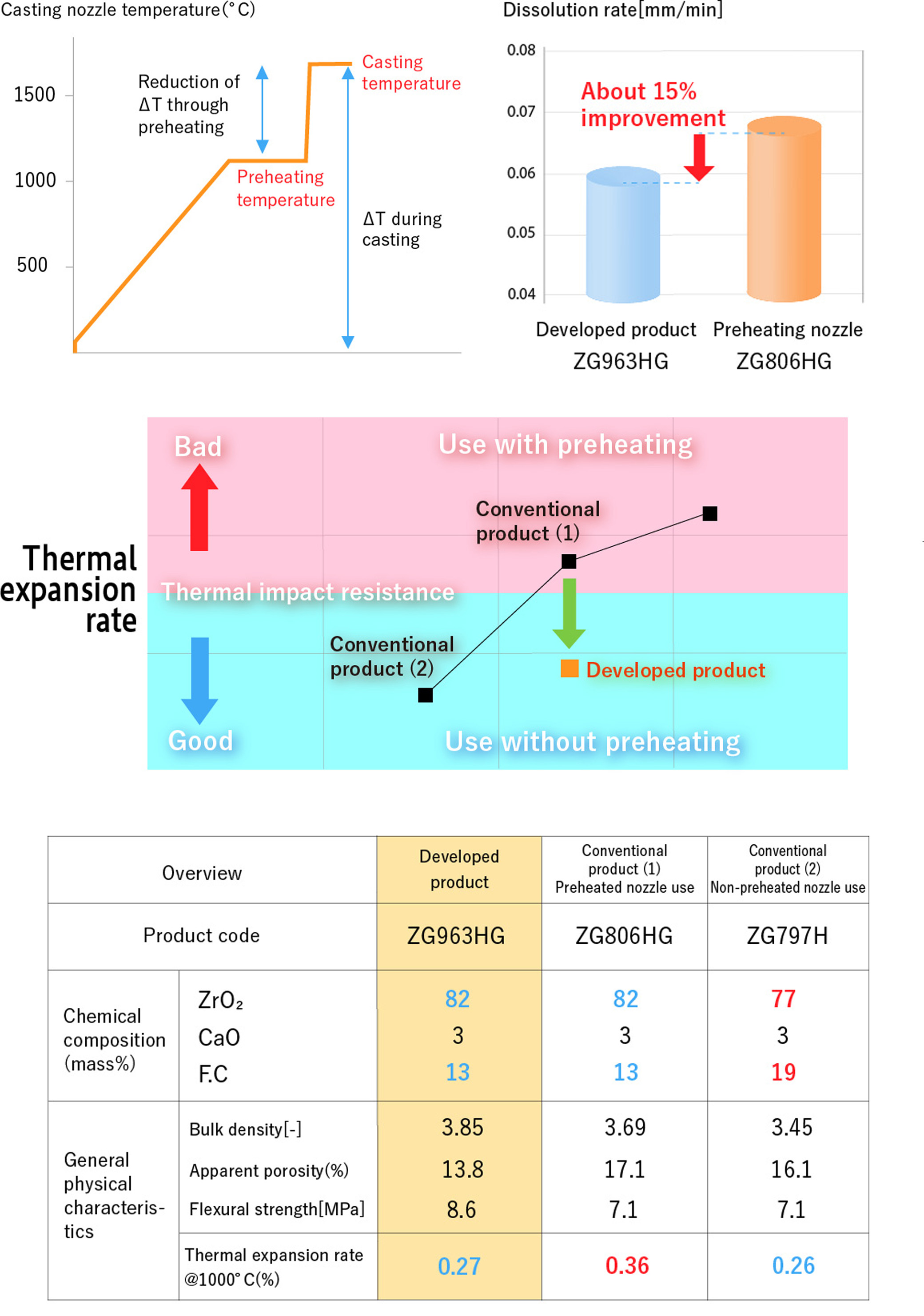

Non-preheating casting nozzle

Non-preheating casting nozzle

Can be used without preheating through the suppression of the thermal expansion rate.

As molten steel with temperatures of 1500℃ or higher passes through the nozzle for casting, there is a risk of cracking due to large temperature differences(ΔT). Therefore, conventional product (1) requires preheating to reduce ΔT and conventional product (2), which is not preheated, has the problem of low durability.

The product we have developed has the same amount of carbon as conventional product (1), but it can be used without preheating through the suppression of the thermal expansion rate, with a durability equal to or better than (1). The energy consumption rate is reduced by no preheating (equivalent to 40kg-CO2/nozzle).

List of Carbon Neutral Initiatives

List of Carbon Neutral Initiatives

Development of a no-need-to-dry gunning material

Non-preheating casting nozzle

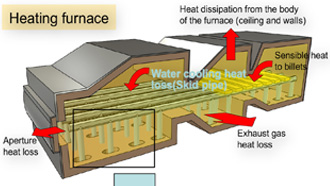

New KSB construction method for heating furnace skid pipes

Energy-saving technology for industrial furnaces using insulation materials

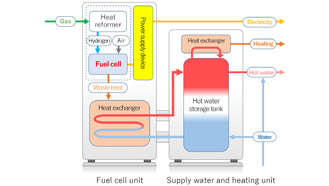

Insulation material used for Ene-Farm components

Insulation material used for battery components for EV vehicles