Carbon Neutral Initiatives

Development of a no-need-to-dry gunning material

Development of a no-need-to-dry gunning material

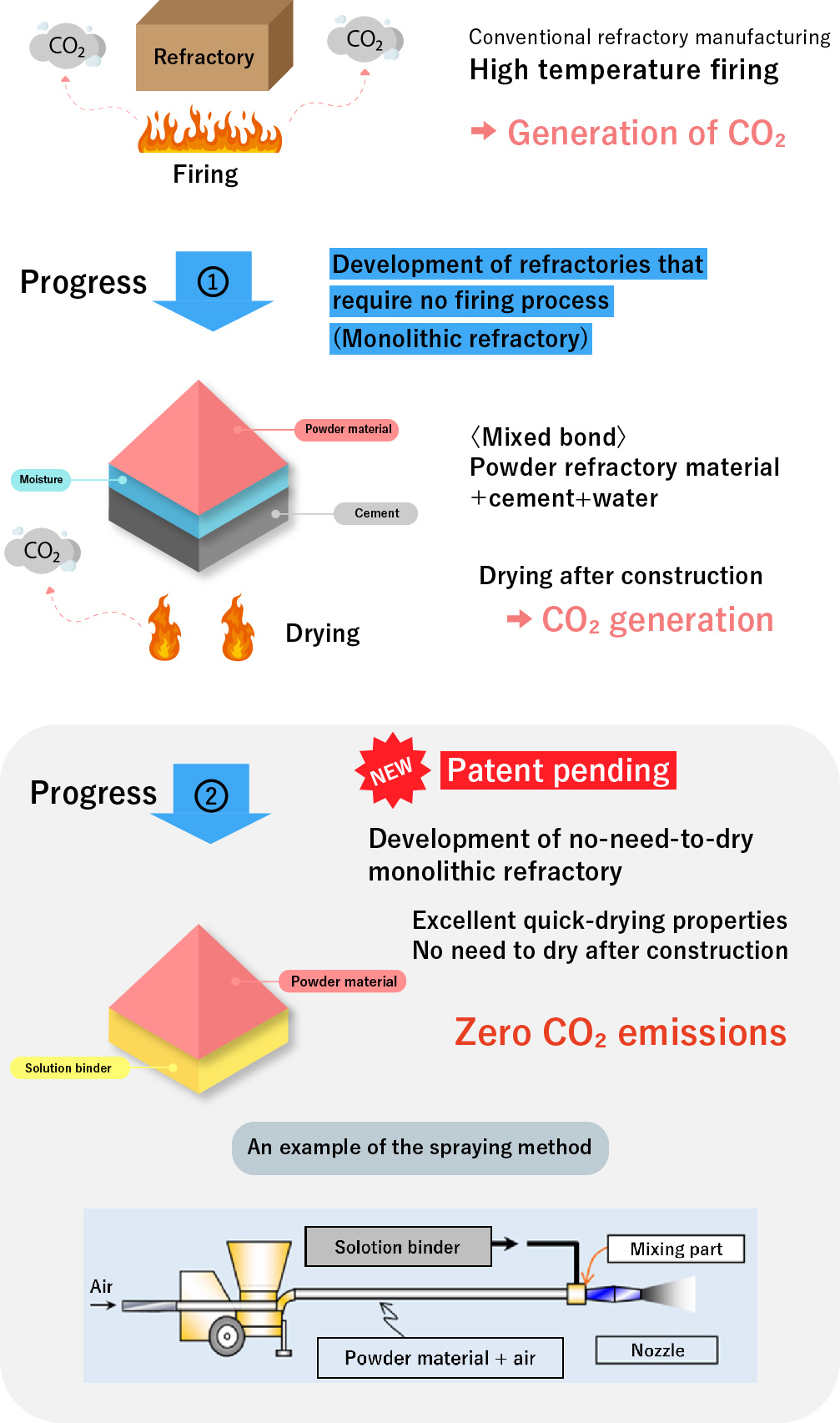

Conventional refractory manufacturing has achieved precise performance through high-temperature firing. However, a large amount of CO2 is generated by this production process. As such, we worked toward developing refractories that do not generate CO2. The technology progressed and with the development of a powder refractory material, we succeeded in creating a refractory material that is not fired, and moreover, succeeded in making a monolithic refractory by mixing and bonding powdered refractory material and cement with water. However, even in this production process, drying was required to remove moisture and CO2 was still generated. Further technological advances have made drying after construction unnecessary through the development of a solution binder with excellent quick-drying properties. With this production process, we were able to reduce CO2 emission to zero. This new technology is currently patent pending.

List of Carbon Neutral Initiatives

List of Carbon Neutral Initiatives

Development of a no-need-to-dry gunning material

Non-preheating casting nozzle

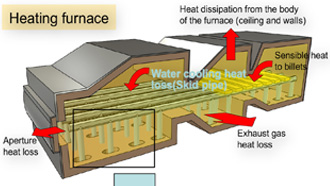

New KSB construction method for heating furnace skid pipes

Energy-saving technology for industrial furnaces using insulation materials

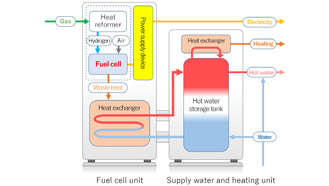

Insulation material used for Ene-Farm components

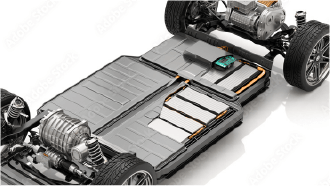

Insulation material used for battery components for EV vehicles