Carbon Neutral Initiatives

We will contribute to the realization of a carbon-free society

Carbon Neutral 2050 Objectives

We will contribute to the realization of a carbon-free society with our “heat management” technology.

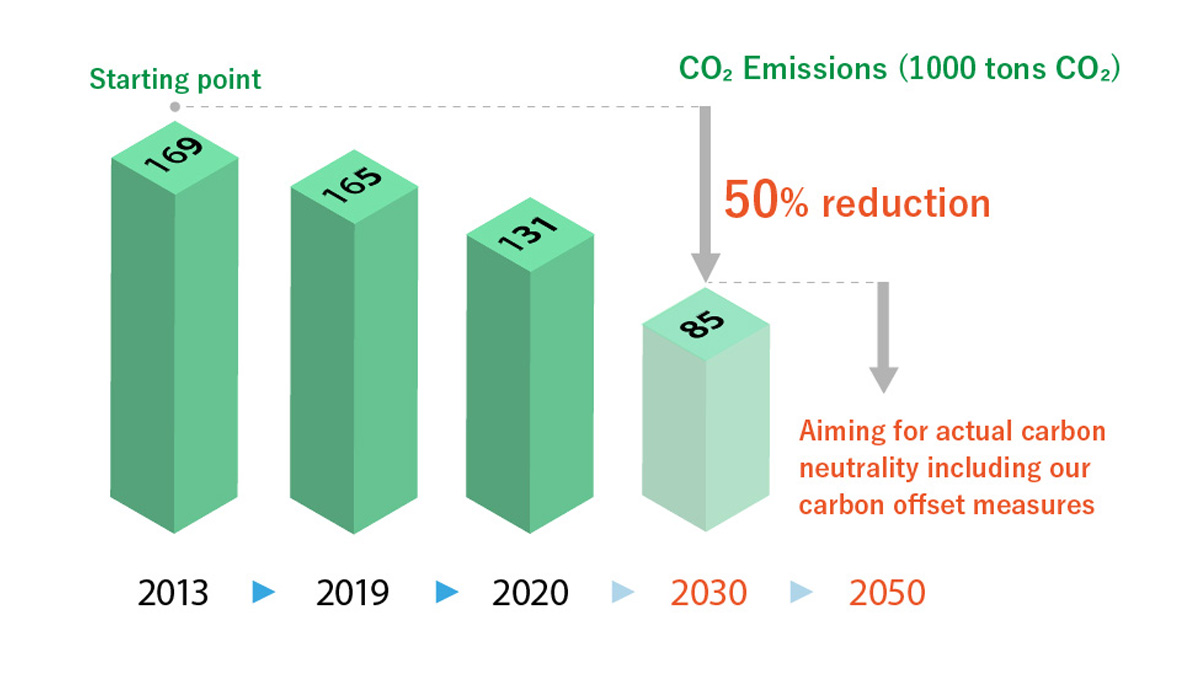

In regards to CO2 emitted by our business activities,

- We will reduce total CO2 emissions by 50% by 2030, compared to those of 2013

- We will aim to be effectively carbon neutral by 2050 taking into account carbon offset measures

More specifically, we will proceed with the following initiatives:

- Conversion to products and businesses with low CO2 emissions.

- (eg.) Firing refractories to unburnt.

- Shifting to monolithic or precast blocks, etc.

- Expansion of recycled landscape bricks production, etc.

- The consolidation and streamlining of manufacturing equipment, improvement in manufacturing processes, and renewing aged equipment to improve efficiency and productivity.

- Thorough promotion of energy-conserving operations and the utilization of waste heat circulation using furnace design technology.

- The application of heat shielding and insulating sheets utilizing our heat-insulating products.

- Further conversion to LNG with low CO2 emissions, from heavy oil and LPG, increasing electrification, a complete installation of LED lighting, and introduction of a power-conservation system with thorough management of heating and cooling system temperatures.

Contributions to the customers who use our products

In addition, when customers use our products, we contribute to the reduction of their CO2 emissions.

To make that happen, we will proceed with the following initiatives:

- Development of low heat conducting refractories and non-preheated refractories in our refractory business and others.

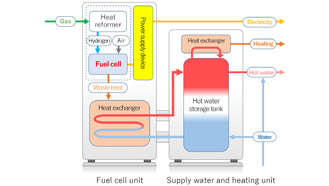

- Expansion to the application of heat insulating materials and fine ceramics for fuel cells, power generation, steel and industrial furnaces in the ceramics business, and the development and application of lightweight setters for high-speed condenser firing furnaces.

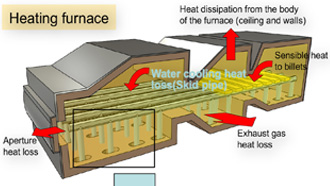

- Energy-saving industrial furnace design and low-heat conduction refractory construction in the furnace business, and expansion of orders in the environmental field, such as in biomass power generation.

List of Carbon Neutral Initiatives

List of Carbon Neutral Initiatives

Development of a no-need-to-dry gunning material

Non-preheating casting nozzle

New KSB construction method for heating furnace skid pipes

Energy-saving technology for industrial furnaces using insulation materials

Insulation material used for Ene-Farm components

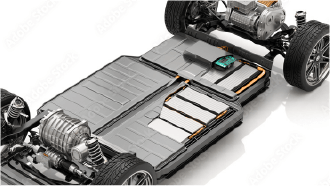

Insulation material used for battery components for EV vehicles